High temperature 1450c refractory fiber module insulation aluminum silicate ceramic fiber module

- $0.10 / >=500 kilograms

- 500 kilograms

- Zhengzhou Rongsheng Import And Export Co., Ltd.

- Henan, China

- Mr Rongsheng Refractory

Product Detail

| application: | industrial furnace | Density (kg/cubic meter): | 160-220 |

| Temperature (℃): | 1260/1260/1350/1430 | Packaging details: | Standard export packaging: 1. Inner plastic bag, outer woven bag. 2. According to customer's requirements. |

| describe: | BIOWOO 1100/1300 module | port: | Shanghai, Qingdao, etc. |

| Silica: | 54/55/47/49 | Supply capacity: | Daily production of 100 tons of refractory ceramic fiber blanket 25mm thick |

| product name: | Fireproof ceramic fiber module | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, PayPal |

| grade: | HP/HA/HZ module | feature: | Fireproof |

| Certificate: | ISO9001 | Package preview: | |

| color: | white | Aluminum oxide: | 43/44/52/35 |

Product Description

Ceramic fiber module description

Ceramic fiber modules are compressed using ceramic fiber blankets. Ceramic fiber modules are produced using various anchoring systems. They are white in color, regular in size, have good refractory and heat insulation effects, and have a graded temperature of 1050-1600°C. They are used for various kiln lining insulation and various insulation materials. Equipment lining.

feature

Low bulk density and low thermal conductivity.

Resistance to thermal shock and airflow erosion.

Excellent mechanical strength and good internal anchor safety

Easy to install. After installation, the lining forms a seamless space with good thermal insulation effect.

Low bulk density and low thermal conductivity.

Resistance to thermal shock and airflow erosion.

Excellent mechanical strength and good internal anchor safety

Easy to install. After installation, the lining forms a seamless space with good thermal insulation effect.

Ceramic fiber modules can be divided into the following types according to temperature levels

1050℃ ordinary ceramic fiber module

1260℃ standard ceramic fiber module

1260℃ high purity ceramic fiber module

1350℃ high alumina ceramic fiber module

1430℃ zirconium ceramic fiber module

1600℃ ceramic fiber module

Specification

Ceramic fiber module | RS1050 | RS1260ST | RS1260HP | RS1350 ha | RS1430 zirconium | RS1600 PMF | ||||

Classification temperature | 1050 | 1260 | 1260 | 1350 | 1430 | 1600 | ||||

192kg/m3/at()℃/24h linear shrinkage | ≤2.0 (850℃) | ≤2.0 (1000℃) | ≤2.0 (1050℃) | ≤2.0 (1100℃) | ≤2.5 (1200℃) | ≤1.5 (1450℃) | ||||

Density(KG/M3) | 172-240 | 172-240 | 172-240 | 172-240 | 172-240 | 172-240 | ||||

Thermal conductivity (W/mk) | 400℃ | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | - | |||

600℃ | 0.15 | 0.15 | 0.15 | 0.12 | 0.12 | 0.12 | ||||

800℃ | 0.22 | 0.20 | 0.19 | 0.18 | 0.16 | 0.15 | ||||

1000℃ | - | - | 0.22 | 0.12 | 0.19 | 0.18 | ||||

chemical composition(%) | Aluminum oxide | 42-44 | 45-46 | 47-49 | 52-55 | 34-36 | 72-75 | |||

Alumina + Silica | ≥99.0 | ≥99.0 | ≥99.0 | ≥99.0 | ≥99.0 | ≥99.0 | ||||

Zirconia | - | - | - | - | 15-17th | - | ||||

other | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ||||

Applications

1. Steel industry: heat treatment furnace, ladle cover, annealing furnace, rotary furnace, bell furnace, walking beam furnace, hot air, smoke pipe, etc. 2. Ceramic industry: tunnel kiln, shuttle kiln, end-flame furnace, roller kiln. 3. Petrochemical industry: atmospheric furnace, reforming furnace, coking furnace, cracking furnace, flue, etc. 4. Heat treatment industry: annealing furnace, normalizing furnace, drawing furnace, pit furnace, kiln car. 5. High temperature equipment: such as boiler furnaces, resistance furnaces and other types of industrial furnaces. 6. Green energy industry: garbage incinerator, RTO exhaust gas treatment furnace, SCR environmentally friendly catalytic furnace, etc.

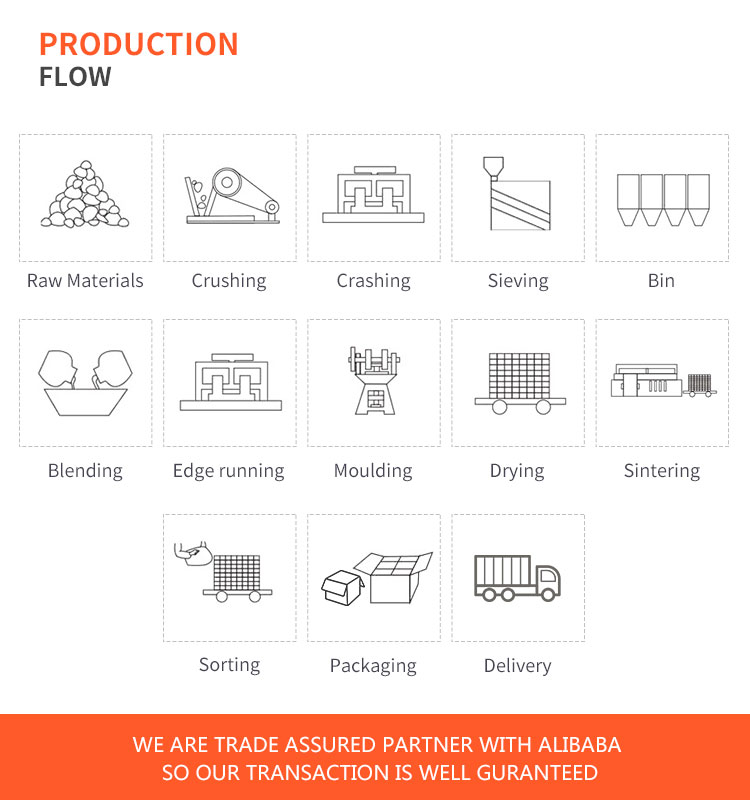

Production Process

VIEW MORE

Related Products

-

Fefraticory price biosoluble fiber optic module

Product Description Biowool® module Biowool® modules are made of compressed soluble fiber blankets. This module is specially designed to meet the thermal insulation requirements of industrial furnaces under certain special thermal conditions. BiOwool® modules are produced by a variety of anchoring..... -

LKT high quality ceramic fiber modules with anchors for ceramic flat top kilns, good price and good thermal insulation

Density (kg/m3): 250-300 Payment Terms: L/C, Western Union, D/P, D/A, T/T, PayPal Operating Temperature: 1050/1260/1350/1430/1600c/1260c Supply Ability: 2000 tons per month Classification temperature(℃): 1260 color: White Thermal Conductivity: 5% feature: Fire prevention Fiber Diameter: 3-5 microns.... -

1260 furnace insulation block high temperature resistant ceramic fiber module with anchor bolts

Anchor components: SS304 Packaging details: Carton/pallet density: 220/220/240kg/cubic meter Thermal Conductivity: 0.09 Package: Woven bags/pallets feature: Fireproof Package preview: port: Qingdao PortShanghai PortTianjin PortNingbo Port size: 300*300*300mm 300*300*250mm payment terms: L/C,...... -

custom refractory Insulation Ceramic fiber tape Ceramic fiber tape

application: Furnace insulation pay: wire transfer Packaging Details: The inside is a plastic bag, the outside is a carton or customized according to customer requirements size: customizable Package preview: Operating temperature: 1050℃~1350℃ product name: ceramic fiber tape Supply capacity: 5000...... -

HT-High Quality Furnace/Alumina Fiber Module Heater

Origin: Henan, China (Mainland) feature: fire protection payment terms: L/C, Western Union, T/T Supply capacity: 500 tons per month density: 400-500 kg/m3 Packaging Details: Standard export packaging port: Qingdao Shanghai size: client needs type: 1800 application: insulation product name:...... -

High Thermal Efficiency Refractory Ceramic Fiber Module for RTO Furnace Lining

Aluminum oxide: 45-46% Packaging Details: Packed in cartons or stacked on pallets Al2O3+SiO2: 98% Package preview: Packing: Carton/Pallet: Carton/Pallet feature: fire protection Operating temperature: 1260°C payment terms: L/C, T/T port: Shanghai Port/Shandong Port color: white Supply capacity: 100.... -

1260C Induction Furnace Lining Material Aluminum Silicate Refractory Material Khmer Insulation Ceramic Fiber Module

Bulk density: 96kg/m3-128kg/m3-160kg/m3 feature: Excellent tensile strength, fireproof Material: Ceramic fiber Package preview: product name: Ceramic Fiber Module AL2O3+SIO2: 96% payment terms: L/C, D/P, D/A, T/T port: Qingdao Application of ceramic fiber blanket: Insulation field Supply capacity:..... -

1260C thermal insulation ceramic fiber module 1430C thermal insulation module factory direct sales thermal insulation module density 220kg/m3

port: Qingdao feature: fire protection Melting point: 1575°C Packaging Details: 1. Packed in moisture-proof paper 2. Packed in kraft paper 3 Packed in plywood box with foam plastic on all sides. 4. Silicon carbide tube plywood box packaging products Classification temperature: 1260°C, 1430°C Supply.... -

High quality insulation module 1350C Ceramic fiber seam module

Heating permanent wire shrinkage: 2% (1000℃*24 hours) Aluminum oxide: 52%-55% Bulk density (kg/m3): 160kg/m3-240kg/m3 Package preview: Supply capacity: 30 tons of ceramic fiber modules per day port: Qingdao/Tianjin/Shanghai/Lianyungang Classification temperature (°C): 1350°C product name: Ceramic...... -

Hot sale material heater refractory heating ceramic fiber module

Common size: 300*300*300MM/Customized payment terms: L/C, T/T port: Tianjin Supply capacity: 50 metric tons per month feature: fire protection Packaging Details: Polyethylene bag+carton+pallet product name: Ceramic Fiber Module Operating temperature: 1000-1430℃ Product Description Ceramic Fiber......