High quality insulation module 1350C Ceramic fiber seam module

- $1.90 / >=500 kilograms

- 500 kilograms

- Zhengzhou Kerui (Group) Refractory Co., Ltd.

- Henan, China

- Ms Lydia Chou

Product Detail

| Heating permanent wire shrinkage: | 2% (1000℃*24 hours) | Aluminum oxide: | 52%-55% |

| Bulk density (kg/m3): | 160kg/m3-240kg/m3 | Package preview: | |

| Supply capacity: | 30 tons of ceramic fiber modules per day | port: | Qingdao/Tianjin/Shanghai/Lianyungang |

| Classification temperature (°C): | 1350°C | product name: | Ceramic Fiber Module |

| feature: | fire protection | Packaging Details: | There are PVC bag cartons inside the carton. |

| Fiber Diameter: | 3-5 microns | Thermal conductivity 400°C (W/mk): | 0.08W/mk |

| color: | white | model: | GB/T JQ-605ST |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Certificate: | ISO9001:2015 |

High Quality Ceramic Fiber Sewing Module 1350C Insulation Module

Our ceramic fiber modules are carefully manufactured with high-grade ceramic fibers, processed through advanced technology to form a strong and flexible module, the fibers are interwoven and assembled into prefabricated blocks, which have excellent thermal insulation performance and easy installation.

Main features:

1. Excellent thermal insulation performance

Ceramic fiber modules excel in insulating furnaces, boilers and other high temperature equipment, reducing heat loss and increasing energy efficiency.

2. Modular design

The module's modular construction allows flexible installation and can be easily adapted to various shapes and configurations, reducing downtime during maintenance.

3. Low thermal conductivity

The low thermal conductivity of our modules ensures excellent heat resistance and efficient temperature control in critical industrial processes.

4. Quick installation and replacement

The prefabricated design facilitates quick and easy installation, reducing downtime and increasing overall productivity.

5. Excellent chemical stability

Our ceramic fiber modules have excellent chemical stability against most acids, bases and corrosive substances, ensuring longevity and reliability.

Product total solid solubility:

|

Ceramic Fiber Module |

HR1050 |

HR1260ST |

HR1260HP |

HR1350HA |

HR1430Zr |

HR1600PMF |

|

|

Classification temperature, ℃ |

1050 |

1260 |

1260 |

1350 |

1430 |

1600 |

|

|

Linear shrinkage,% |

≤2.0 |

≤2.0 |

≤2.0 |

≤2.0 |

≤2.5 |

≤1.5 |

|

|

Volume and density, kg/m3 |

172-240 |

172-240 |

172-240 |

172-240 |

172-240 |

172-240 |

|

|

Thermal conductivity, W/mk

|

400°C |

0.08 |

0.08 |

0.08 |

0.08 |

0.08 |

- |

|

600°C |

0.15 |

0.15 |

0.15 |

0.12 |

0.12 |

0.12 |

|

|

800℃ |

0.22 |

0.2 |

0.19 |

0.18 |

0.16 |

0.15 |

|

|

1000℃ |

- |

- |

0.22 |

0.12 |

0.19 |

0.18 |

|

|

Chemical analysis, %

|

Aluminum oxide |

42-44 |

45-46 |

47-49 |

52-55 |

34-36 |

72-75 |

|

Alumina + Silica |

≥99.0 |

≥99.0 |

≥99.0 |

≥99.0 |

≥99.0 |

≥99.0 |

|

|

Zirconia |

- |

- |

- |

- |

15-17 days |

- |

|

|

others |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

≤1.0 |

|

application:

Industrial furnaces and kilns: Ceramic fiber modules are widely used in the lining of walls, roofs and doors of industrial furnaces and kilns, providing optimum thermal insulation and energy efficiency.

Boilers and Heaters: Used in boilers and heaters to enhance thermal insulation and ensure uniform and stable temperature distribution for efficient operation.

Thermal processing equipment: Our modules are used as lining materials for thermal processing equipment, providing excellent thermal insulation and improving temperature uniformity.

Incinerators and Combustion Chambers: It is used in incinerators and combustion chambers to prevent heat loss and facilitate an efficient combustion process.

High Temperature Duct Lining: The ceramic fiber modules act as a highly efficient duct lining ensuring minimal heat loss in hot air and gas delivery systems.

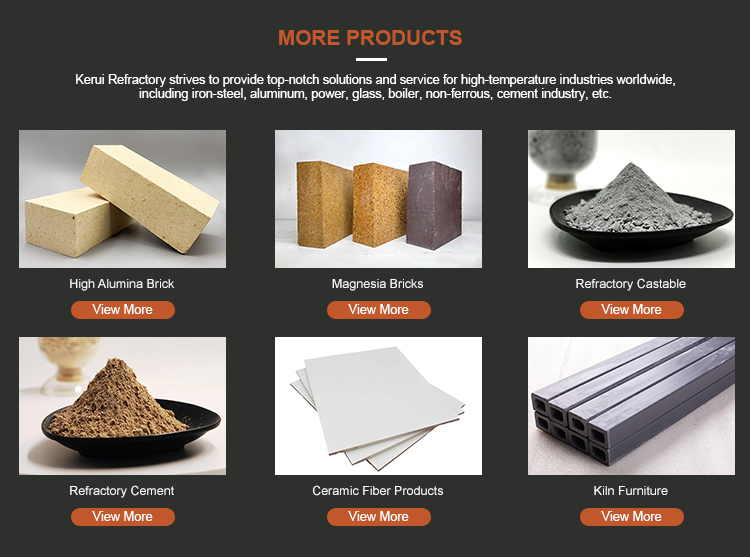

Related Products

-

Fefraticory price biosoluble fiber optic module

Product Description Biowool® module Biowool® modules are made of compressed soluble fiber blankets. This module is specially designed to meet the thermal insulation requirements of industrial furnaces under certain special thermal conditions. BiOwool® modules are produced by a variety of anchoring..... -

LKT high quality ceramic fiber modules with anchors for ceramic flat top kilns, good price and good thermal insulation

Density (kg/m3): 250-300 Payment Terms: L/C, Western Union, D/P, D/A, T/T, PayPal Operating Temperature: 1050/1260/1350/1430/1600c/1260c Supply Ability: 2000 tons per month Classification temperature(℃): 1260 color: White Thermal Conductivity: 5% feature: Fire prevention Fiber Diameter: 3-5 microns.... -

High temperature 1450c refractory fiber module insulation aluminum silicate ceramic fiber module

application: industrial furnace Density (kg/cubic meter): 160-220 Temperature (℃): 1260/1260/1350/1430 Packaging details: Standard export packaging: 1. Inner plastic bag, outer woven bag. 2. According to customer's requirements. describe: BIOWOO 1100/1300 module port: Shanghai, Qingdao, etc....... -

1260 furnace insulation block high temperature resistant ceramic fiber module with anchor bolts

Anchor components: SS304 Packaging details: Carton/pallet density: 220/220/240kg/cubic meter Thermal Conductivity: 0.09 Package: Woven bags/pallets feature: Fireproof Package preview: port: Qingdao PortShanghai PortTianjin PortNingbo Port size: 300*300*300mm 300*300*250mm payment terms: L/C,...... -

custom refractory Insulation Ceramic fiber tape Ceramic fiber tape

application: Furnace insulation pay: wire transfer Packaging Details: The inside is a plastic bag, the outside is a carton or customized according to customer requirements size: customizable Package preview: Operating temperature: 1050℃~1350℃ product name: ceramic fiber tape Supply capacity: 5000...... -

HT-High Quality Furnace/Alumina Fiber Module Heater

Origin: Henan, China (Mainland) feature: fire protection payment terms: L/C, Western Union, T/T Supply capacity: 500 tons per month density: 400-500 kg/m3 Packaging Details: Standard export packaging port: Qingdao Shanghai size: client needs type: 1800 application: insulation product name:...... -

High Thermal Efficiency Refractory Ceramic Fiber Module for RTO Furnace Lining

Aluminum oxide: 45-46% Packaging Details: Packed in cartons or stacked on pallets Al2O3+SiO2: 98% Package preview: Packing: Carton/Pallet: Carton/Pallet feature: fire protection Operating temperature: 1260°C payment terms: L/C, T/T port: Shanghai Port/Shandong Port color: white Supply capacity: 100.... -

1260C Induction Furnace Lining Material Aluminum Silicate Refractory Material Khmer Insulation Ceramic Fiber Module

Bulk density: 96kg/m3-128kg/m3-160kg/m3 feature: Excellent tensile strength, fireproof Material: Ceramic fiber Package preview: product name: Ceramic Fiber Module AL2O3+SIO2: 96% payment terms: L/C, D/P, D/A, T/T port: Qingdao Application of ceramic fiber blanket: Insulation field Supply capacity:..... -

1260C thermal insulation ceramic fiber module 1430C thermal insulation module factory direct sales thermal insulation module density 220kg/m3

port: Qingdao feature: fire protection Melting point: 1575°C Packaging Details: 1. Packed in moisture-proof paper 2. Packed in kraft paper 3 Packed in plywood box with foam plastic on all sides. 4. Silicon carbide tube plywood box packaging products Classification temperature: 1260°C, 1430°C Supply.... -

Hot sale material heater refractory heating ceramic fiber module

Common size: 300*300*300MM/Customized payment terms: L/C, T/T port: Tianjin Supply capacity: 50 metric tons per month feature: fire protection Packaging Details: Polyethylene bag+carton+pallet product name: Ceramic Fiber Module Operating temperature: 1000-1430℃ Product Description Ceramic Fiber......