High Thermal Efficiency Refractory Ceramic Fiber Module for RTO Furnace Lining

- $2.10 / >=30 pieces

- 30 pieces

- Jiangsu Cera Thermal Technology Co., Ltd.

- Jiangsu, China

- Ms Crystal Yu

Product Detail

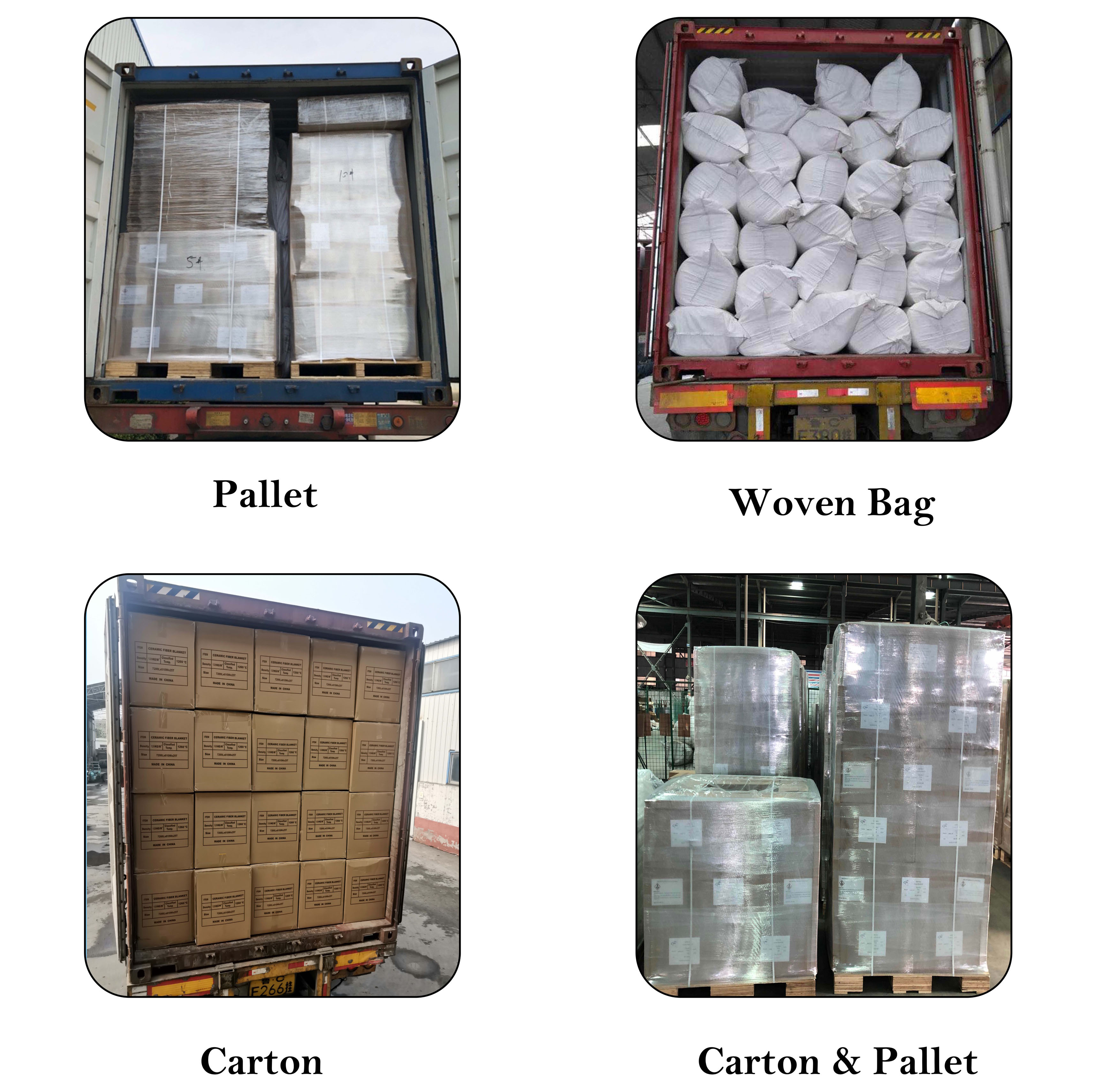

| Aluminum oxide: | 45-46% | Packaging Details: | Packed in cartons or stacked on pallets |

| Al2O3+SiO2: | 98% | Package preview: | |

| Packing: Carton/Pallet: | Carton/Pallet | feature: | fire protection |

| Operating temperature: | 1260°C | payment terms: | L/C, T/T |

| port: | Shanghai Port/Shandong Port | color: | white |

| Supply capacity: | 100 pallets per week | Density (kg/m3): | 180/190/200/210/240 |

Fireproof high thermal efficiency ceramic fiber module for RTO furnace lining

- Anchoring on the back allows in-line installation and parquet installation.

- The reduced pressure of the blanket fold keeps the inter-module joints tightly sealed in both configurations

- Elastic blanket resists mechanical damage

- Low thermal conductivity, high thermal efficiency

- Total Thermal Shock Resistance

- No drying or curing required - ready for production immediately after installation

- Anchor point away from module hot face

|

type |

CT-1000 |

CT-1260 |

CT-1360 |

CT-1430 |

CT-1500 |

CT-1600 |

|

Grading temperatureohC |

1100 |

1260 |

1360 |

1430 |

1500 |

1600 |

|

Density (kg/m33)density |

170,190,210 |

170,190,200 |

||||

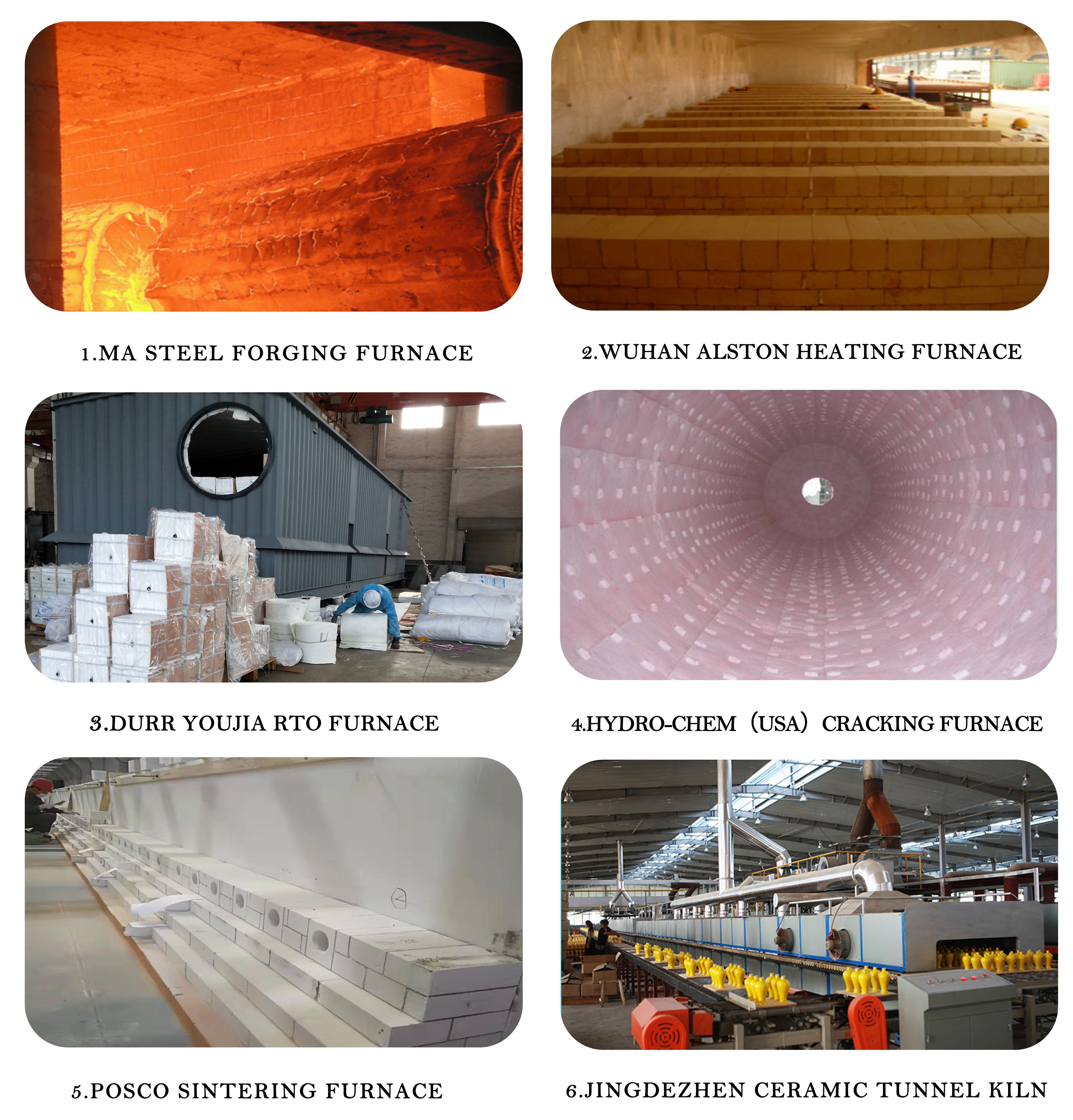

- Heat treatment: annealing furnace, tempering furnace, soaking furnace, etc.

- Ceramics: firing tunnels and intermittent kilns for white porcelain, sanitary ware, bricks.

- Steel: transfer ladle cover, soaking pit cover, heating furnace, continuous annealing furnace, lift-off furnace

- Petrochemical: ethylene pyrolysis furnace, reformer, atmospheric/vacuum pressure furnace, pipeline pyrolysis heater

- Aluminum: soaking pits and covers, pack furnaces, homogenization and piping systems

- Utilities: waste heat recovery units, combustion chambers and boiler piping

Jiangsu Sairui Thermal Energy Technology Co., Ltd. was formerly known as Nanjing Sairui Material Technology Co., Ltd. The company's main business includes refractory material production, furnace lining design, high-temperature thermal engineering, and kiln construction.

Refractory equipment, research and development, sales. Through years of cooperation with Morgan Thermal Ceramics, we have accumulated rich experience in a large number of engineering projects.

Our tenet is: quality and reputation are fundamental, technology and service are life.

- In 2002, Nanjing Sairui Material Technology Co., Ltd. was established

- Nanjing factory was established in 2005.

- Established Suzhou SLMC Thermal Insulation Material Co., Ltd. in 2009

- In 2010, Shandong Zibo Baoyang Refractory Fiber Co., Ltd. was established

- In 2013, Thermtec Insulation (Zhejiang) Co., Ltd. was established.

- In 2013, Jiangsu Saila Thermal Energy Technology Co., Ltd. was established

Comment

Values given herein are typical average values obtained according to accepted test methods

and are subject to normal manufacturing variances. they are provided as a technical service, and

Subject to change without notice. Therefore, the data contained here should not be used for normative purposes.

Related Products

-

Fefraticory price biosoluble fiber optic module

Product Description Biowool® module Biowool® modules are made of compressed soluble fiber blankets. This module is specially designed to meet the thermal insulation requirements of industrial furnaces under certain special thermal conditions. BiOwool® modules are produced by a variety of anchoring..... -

LKT high quality ceramic fiber modules with anchors for ceramic flat top kilns, good price and good thermal insulation

Density (kg/m3): 250-300 Payment Terms: L/C, Western Union, D/P, D/A, T/T, PayPal Operating Temperature: 1050/1260/1350/1430/1600c/1260c Supply Ability: 2000 tons per month Classification temperature(℃): 1260 color: White Thermal Conductivity: 5% feature: Fire prevention Fiber Diameter: 3-5 microns.... -

High temperature 1450c refractory fiber module insulation aluminum silicate ceramic fiber module

application: industrial furnace Density (kg/cubic meter): 160-220 Temperature (℃): 1260/1260/1350/1430 Packaging details: Standard export packaging: 1. Inner plastic bag, outer woven bag. 2. According to customer's requirements. describe: BIOWOO 1100/1300 module port: Shanghai, Qingdao, etc....... -

1260 furnace insulation block high temperature resistant ceramic fiber module with anchor bolts

Anchor components: SS304 Packaging details: Carton/pallet density: 220/220/240kg/cubic meter Thermal Conductivity: 0.09 Package: Woven bags/pallets feature: Fireproof Package preview: port: Qingdao PortShanghai PortTianjin PortNingbo Port size: 300*300*300mm 300*300*250mm payment terms: L/C,...... -

custom refractory Insulation Ceramic fiber tape Ceramic fiber tape

application: Furnace insulation pay: wire transfer Packaging Details: The inside is a plastic bag, the outside is a carton or customized according to customer requirements size: customizable Package preview: Operating temperature: 1050℃~1350℃ product name: ceramic fiber tape Supply capacity: 5000...... -

HT-High Quality Furnace/Alumina Fiber Module Heater

Origin: Henan, China (Mainland) feature: fire protection payment terms: L/C, Western Union, T/T Supply capacity: 500 tons per month density: 400-500 kg/m3 Packaging Details: Standard export packaging port: Qingdao Shanghai size: client needs type: 1800 application: insulation product name:...... -

1260C Induction Furnace Lining Material Aluminum Silicate Refractory Material Khmer Insulation Ceramic Fiber Module

Bulk density: 96kg/m3-128kg/m3-160kg/m3 feature: Excellent tensile strength, fireproof Material: Ceramic fiber Package preview: product name: Ceramic Fiber Module AL2O3+SIO2: 96% payment terms: L/C, D/P, D/A, T/T port: Qingdao Application of ceramic fiber blanket: Insulation field Supply capacity:..... -

1260C thermal insulation ceramic fiber module 1430C thermal insulation module factory direct sales thermal insulation module density 220kg/m3

port: Qingdao feature: fire protection Melting point: 1575°C Packaging Details: 1. Packed in moisture-proof paper 2. Packed in kraft paper 3 Packed in plywood box with foam plastic on all sides. 4. Silicon carbide tube plywood box packaging products Classification temperature: 1260°C, 1430°C Supply.... -

High quality insulation module 1350C Ceramic fiber seam module

Heating permanent wire shrinkage: 2% (1000℃*24 hours) Aluminum oxide: 52%-55% Bulk density (kg/m3): 160kg/m3-240kg/m3 Package preview: Supply capacity: 30 tons of ceramic fiber modules per day port: Qingdao/Tianjin/Shanghai/Lianyungang Classification temperature (°C): 1350°C product name: Ceramic...... -

Hot sale material heater refractory heating ceramic fiber module

Common size: 300*300*300MM/Customized payment terms: L/C, T/T port: Tianjin Supply capacity: 50 metric tons per month feature: fire protection Packaging Details: Polyethylene bag+carton+pallet product name: Ceramic Fiber Module Operating temperature: 1000-1430℃ Product Description Ceramic Fiber......