High Density Refractory Bricks for Pizza Ovens and Fireplaces

- $0.12 /unit

- 1 unit

- Zibo Soaring Universe Refractory & Insulation Materials Co., Ltd.

- Shandong, China

- Ms Linda Mu

Product Detail

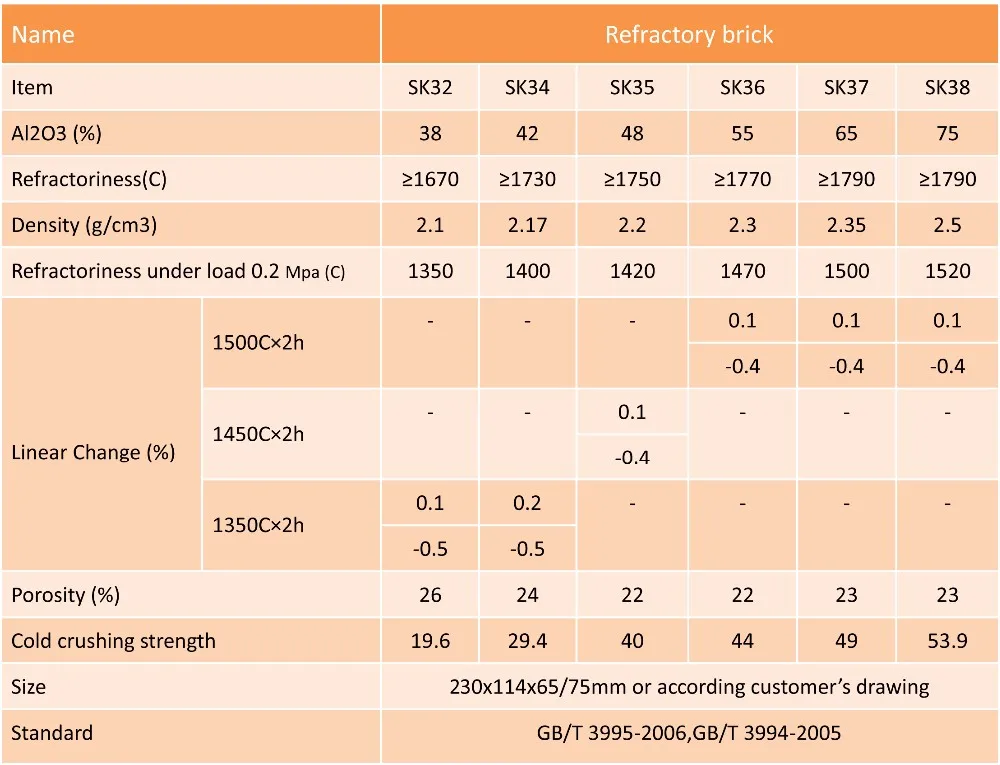

| Silicon carbide content (%): | - | Refractoriness (degrees): | Ordinary (1580° |

| Supply capacity: | 5000 tons per month | brand: | Centrum |

| model: | SK36 | Packaging Details: | 1) Wooden pallet with plastic film. 2) Each 20ft container can load 24MT 3) As customer's requirement. |

| MgO content (%): | - | Al2O3 content (%): | 55% |

| Silica content (%): | 42 | size: | 230*114*65/75mm |

| CaO content (%): | - | Certificate: | BV, SASO, ROHS, SGS, ISO9001:2000, CE |

| CrO content (%): | - | Origin: | Shandong China |

| Maximum refractory temperature: | 1790C | MSDSs are available: | Yes |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, Paypal, Cash | port: | Qingdao |

| sample: | usable | Material: | other |

| application: | pizza oven | shape: | brick |

It can be divided into three processes: raw material, forming and firing. Refractory bricks are generally formed by dry pressing. By uniformly mixing the materials in proportion and aging for a period of time. Then, some powder is poured into the module and dry pressed. The green body after dry pressing needs to be pushed into a drying kiln for drying or air-dried. This progress takes about 3-5 days. After completing this step, the green body is pushed into a tunnel furnace or a shuttle kiln, and fired at a temperature of about 1300C. This progress will take approximately 5-7 days.

The fired bricks are packed in pallets before leaving the factory.

application

•Industrial furnaces, glass furnaces

• Furnaces for the chemical industry

• Utility furnace linings

• Insulated ventilation walls

feature

• High temperature resistance, corrosion resistance, wear resistance

• Excellent compressive strength

• Resistant to acids and alkalis.

• Excellent thermal stability.

Packing of refractory bricks: pallets. Can also be customized according to your needs! !

Related Products

-

BN boron nitride coating for casting materials, aluminum casting coating, die-casting release coating

Product Description Boron nitride coating is a non-toxic, non-polluting and environmentally friendly material that is non-stick and does not penetrate molten metal. It can fully protect the surface of refractory containers that are in direct contact with molten metal and slag, greatly extending the.... -

200 mesh bauxite powder for high temperature kiln in refractory production

Brand Name: Dongtian sample: free size: Size customization Bulk Density: >3.0 MgO content (%): 0.1 Sales Unit: Single item shape: powder Origin: Henan, China Iron Oxide:... -

Good impact resistance cordierite mullite ceramic tube refractory ceramic tube

Place of origin: Jiangsu, China Packaging details: wooden box or carton Refractory degree (degree): Ordinary (1580° Material: cordierite mullite Al2O3 content (%): 48.94 model: HKCD63 Silica content (%): 41.62 Mailing method: DHL, Fedex, UPS or others Key words: Cordierite mullite ceramic tube...... -

China Made Fire Resistant Insulation Material Vermiculite Fire Resistant Insulation Board Vermiculite Board

Packaging details: Fumigated wooden pallet with exterior stretch film and steel foot straps. Refractory degree (degree): Ordinary (1580° brand: cloud field Fire resistance temperature: 1150℃ Silicon carbide content (%): ~ model: vermiculite slab CaO content (%): ~ Supply capacity: Daily output...... -

Low price refractory clay bricks refractory bricks refractory heating furnace boiler kiln industry refractory materials

Supply capacity: 3000 tons of refractory bricks per month color: yellow Operating temperature: 1250-1350 size: client needs Packaging details: 1.International standard airworthy export packaging. 2. Wooden pallets. 3. Wooden/bamboo box (box). 4. Further packaging information will be based on...... -

Silicon Carbide Ceramic Silicon Nitride Si3N4/Sialon Riser Tube for Aluminum Casting

Material: Silicon carbide (SiC) CaO content (%): 0.01 Thermal Conductivity: 0.08W/(meter*K) Refractory degree (degree): Ordinary (1580° Packaging details: The silicon carbide rod has bubble paper inside and a wooden box outside. Moh's hardness: 80-90HRA Magnesium oxide content (%): 0.01 model:...... -

Refractory Bricks Clay Bricks BBQ Pit Price for Glass Oven and Pizza Oven

application: Insulation, fire-resistant lining Ferric oxide%: Maximum 2.5 Load softening temperature (0.2MPa)℃: 1350 minutes Certificate: ISO BV Refractory degree (degree): Ordinary (1580° Bulk density g/cm3: 2.3-2.4kg/cubic meter Al2O3 content (%): 38-42% Silica content (%): 50%~65% port: Qingdao,.... -

230x114x65MM size refractory interlocking clay refractory bricks for kiln

brand: Lecter High temperature cone equivalent Orton cone: 31-32 Package preview: Al2O3 content (%): 36.2 Titanium dioxide(%): 3 Bulk density (kg/m3): 2100-2200 port: Qingdao Na2O+K2O+Li2O(%): 0.5 Material: flint clay Apparent porosity(%): 22-24 Refractoriness (degrees): Ordinary (1580° Supply...... -

High quality lightweight heat insulating refractory bricks jm 23/26/28/30 heat insulating refractory bricks

color: white Operating temperature: 1260 degrees Celsius Aluminum oxide: 35%~40% CaO content (%): 0.01 port: Qingdao Port, Lianyungang application: industrial furnace Material: Mullite Magnesium oxide content (%): 0 shape: brick brand: Shuo Jin Cr2O content (%): 0 payment terms: L/C, Western Union,.... -

Refractory arch brick for pizza oven

Certificate: ISO9001:2000 Cr2O content (%): - shape: brick size: 230x116x65/75 mm Silicon carbide content (%): - model: SK34 Refractoriness (degrees): Ordinary (1580° Material: refractory clay Supply capacity: 5000 tons per month CaO content (%): - Origin: Shandong Province, China Silica content......