Silicon Carbide Ceramic Silicon Nitride Si3N4/Sialon Riser Tube for Aluminum Casting

- $10.00 / >=10 pieces

- 10 pieces

- Liling Xing Tai Long Special Ceramic Co., Ltd.

- Hunan, China

- Ms Anna Peng

Product Detail

| Material: | Silicon carbide (SiC) | CaO content (%): | 0.01 |

| Thermal Conductivity: | 0.08W/(meter*K) | Refractory degree (degree): | Ordinary (1580° |

| Packaging details: | The silicon carbide rod has bubble paper inside and a wooden box outside. | Moh's hardness: | 80-90HRA |

| Magnesium oxide content (%): | 0.01 | model: | XTL-3182 |

| Cr2O content (%): | 0 | size: | as requested |

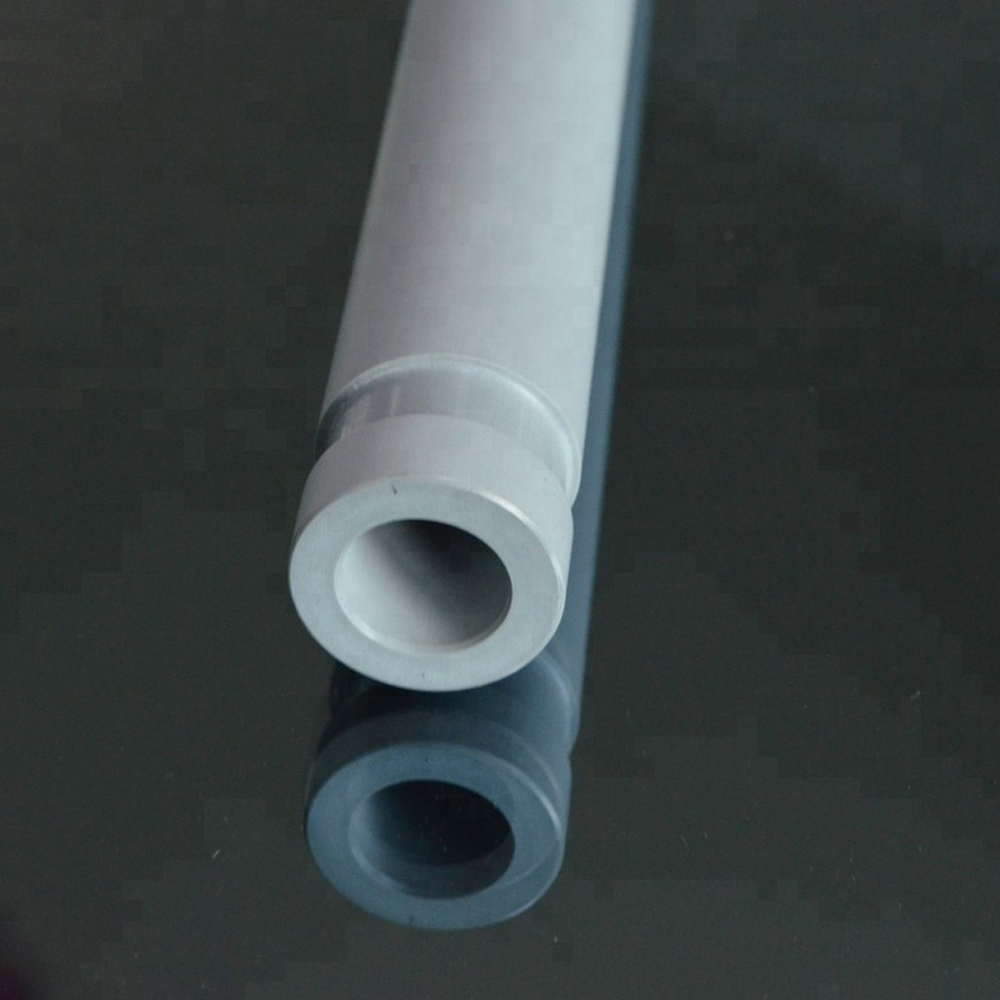

| Maximum operating temperature: | 1700℃ | shape: | pipes, tubes |

| Surface load: | maximum. 13W/cm2 | Place of origin: | Hunan, China |

| Bulk density: | 2.6-3.3g/cubic centimeter | Silicon carbide content (%): | 30-99 |

| port: | Any port in China | length: | 200-1500mm |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | type: | silicon carbide rod |

| Processing services: | cutting | Porosity: | 10-11% |

| brand: | Xingtailong | Supply capacity: | 1,000,000 pieces per month |

| Silica content (%): | 0.1% | Al2O3 content (%): | 0.1% |

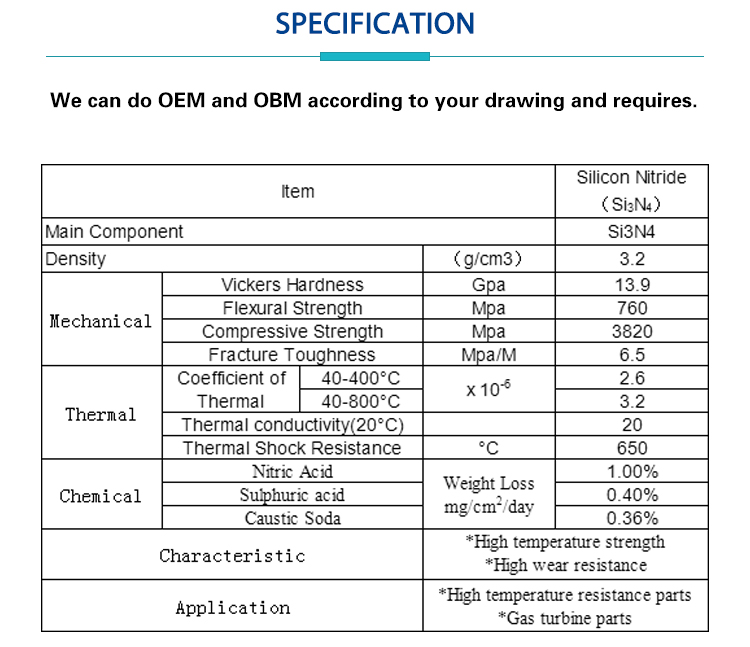

Ceramic silicon carbide silicon nitride Si3N4/Sialon riser tube for aluminum die castings

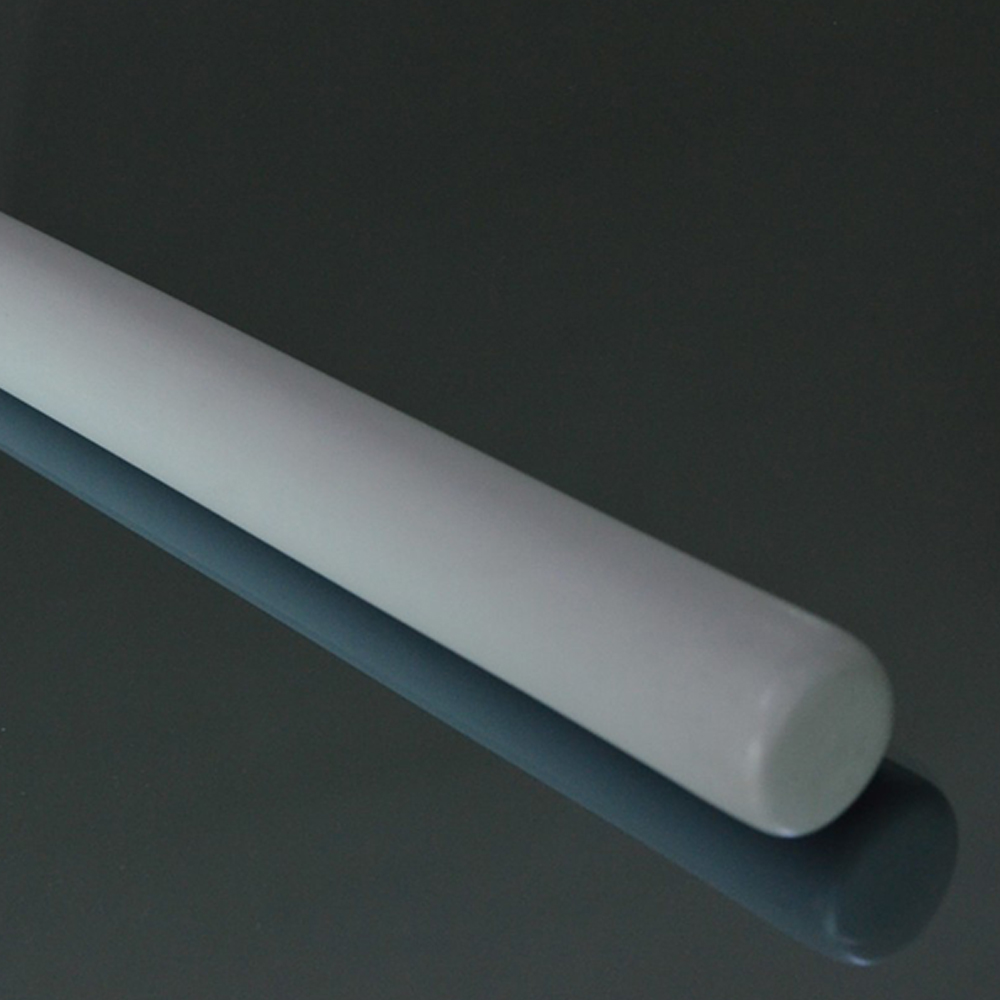

Silicon carbide tube:

1. Professional manufacturer.

2. Silicon carbide rods have a long service life.

3. Best after-sales service.

Silicon carbide tube is Mainly used in the production of aluminum and copperand zinc as lining materials for molten baths and electrolytic cells (reduction cells). The side lining of the reduction tank is corroded by aluminum and cryolite (used as an additive), but the SiC material combined with Si3N4 cannot be corroded by aluminum and does not react chemically with cryolite, so this material is very suitable for use as the lining of the electrolytic cell. brick. In particular, this brick has the excellent properties of high strength, wear resistance and non-conductivity, hence the copolymer (Al2O3 and cryolite). The copolymer protects the working lining like a protective film and increases the service life of the silicon carbide tube electrolyzer.

At the same time, the thermal conductivity of Si3N4 combined with SiC bricks is lower than that of silica bricks, so it can reduce

Side wall thickness or input higher power to expand the load capacity of the electrolyzer and improve

Due to the high resistivity of the material, the side wall power consumption can be reduced by about 15%, which is energy-saving and environmentally friendly for silicon carbide tubes.

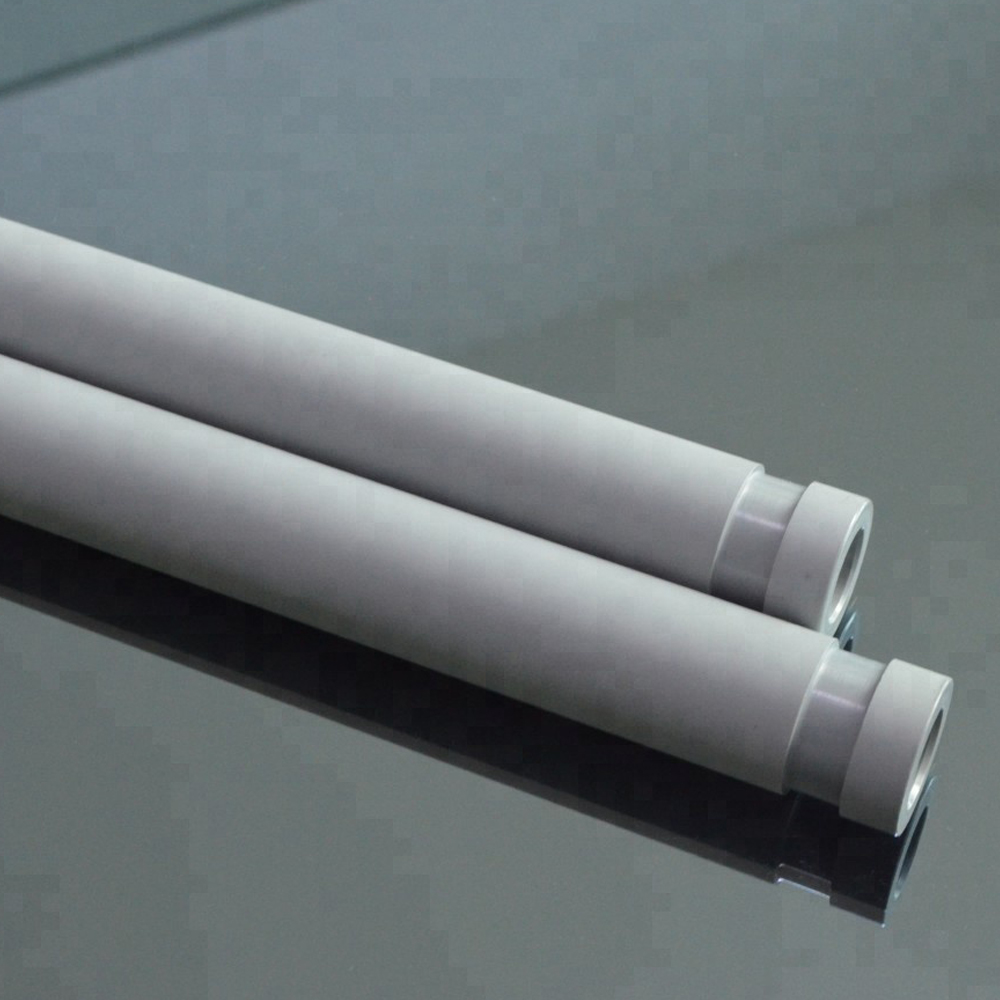

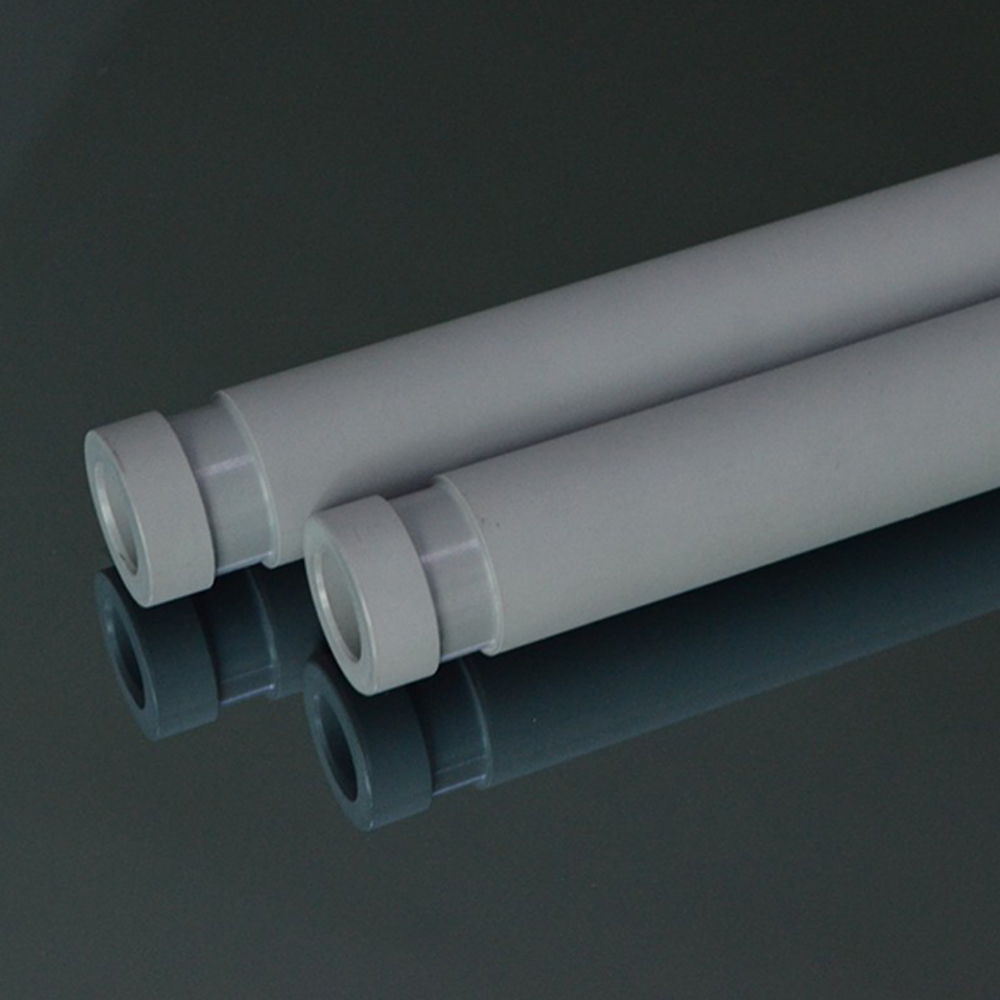

Silicon carbide pipe specifications:

1. The best domestic production technology. Our pipes can be used in aluminum furnaces instead of Japanese pipes.

2 The surface is very smooth to avoid contamination with metal liquid.

3. Good thermal conductivity.

4. High temperature strength.

5. Special groove for easy fixing.

|

density |

2.8 g/cm3 |

|

Porosity |

≤16% |

|

Phase composition |

β-Si3N4, oxide |

|

silicon carbide |

72% |

|

silicon nitride |

twenty one% |

|

Compressive strength |

140 MPa |

|

Bending strength |

35 MPa |

|

Thermal Conductivity |

16W/m*g |

Silicon carbide rod packaging:PE bag inner and outer box (930*630*230mm), and finally make wooden pallet (950*950mm 950*1000mm) or according to your requirements

Transportation of silicon carbide rods:Shipments will be made within 15 days after order confirmation.

Related Products

-

BN boron nitride coating for casting materials, aluminum casting coating, die-casting release coating

Product Description Boron nitride coating is a non-toxic, non-polluting and environmentally friendly material that is non-stick and does not penetrate molten metal. It can fully protect the surface of refractory containers that are in direct contact with molten metal and slag, greatly extending the.... -

200 mesh bauxite powder for high temperature kiln in refractory production

Brand Name: Dongtian sample: free size: Size customization Bulk Density: >3.0 MgO content (%): 0.1 Sales Unit: Single item shape: powder Origin: Henan, China Iron Oxide:... -

Good impact resistance cordierite mullite ceramic tube refractory ceramic tube

Place of origin: Jiangsu, China Packaging details: wooden box or carton Refractory degree (degree): Ordinary (1580° Material: cordierite mullite Al2O3 content (%): 48.94 model: HKCD63 Silica content (%): 41.62 Mailing method: DHL, Fedex, UPS or others Key words: Cordierite mullite ceramic tube...... -

China Made Fire Resistant Insulation Material Vermiculite Fire Resistant Insulation Board Vermiculite Board

Packaging details: Fumigated wooden pallet with exterior stretch film and steel foot straps. Refractory degree (degree): Ordinary (1580° brand: cloud field Fire resistance temperature: 1150℃ Silicon carbide content (%): ~ model: vermiculite slab CaO content (%): ~ Supply capacity: Daily output...... -

Low price refractory clay bricks refractory bricks refractory heating furnace boiler kiln industry refractory materials

Supply capacity: 3000 tons of refractory bricks per month color: yellow Operating temperature: 1250-1350 size: client needs Packaging details: 1.International standard airworthy export packaging. 2. Wooden pallets. 3. Wooden/bamboo box (box). 4. Further packaging information will be based on...... -

Refractory Bricks Clay Bricks BBQ Pit Price for Glass Oven and Pizza Oven

application: Insulation, fire-resistant lining Ferric oxide%: Maximum 2.5 Load softening temperature (0.2MPa)℃: 1350 minutes Certificate: ISO BV Refractory degree (degree): Ordinary (1580° Bulk density g/cm3: 2.3-2.4kg/cubic meter Al2O3 content (%): 38-42% Silica content (%): 50%~65% port: Qingdao,.... -

230x114x65MM size refractory interlocking clay refractory bricks for kiln

brand: Lecter High temperature cone equivalent Orton cone: 31-32 Package preview: Al2O3 content (%): 36.2 Titanium dioxide(%): 3 Bulk density (kg/m3): 2100-2200 port: Qingdao Na2O+K2O+Li2O(%): 0.5 Material: flint clay Apparent porosity(%): 22-24 Refractoriness (degrees): Ordinary (1580° Supply...... -

High quality lightweight heat insulating refractory bricks jm 23/26/28/30 heat insulating refractory bricks

color: white Operating temperature: 1260 degrees Celsius Aluminum oxide: 35%~40% CaO content (%): 0.01 port: Qingdao Port, Lianyungang application: industrial furnace Material: Mullite Magnesium oxide content (%): 0 shape: brick brand: Shuo Jin Cr2O content (%): 0 payment terms: L/C, Western Union,.... -

Refractory arch brick for pizza oven

Certificate: ISO9001:2000 Cr2O content (%): - shape: brick size: 230x116x65/75 mm Silicon carbide content (%): - model: SK34 Refractoriness (degrees): Ordinary (1580° Material: refractory clay Supply capacity: 5000 tons per month CaO content (%): - Origin: Shandong Province, China Silica content...... -

zirconium silicate ball/zirconium silicate for the ceramic industry/zirconium silicate 65%

Origin: Hebei china Magnesium oxide content (%): 0.01% brand: Nada Silicon carbide content (%): custom made color: gray powder pack: 25kg bag port: Tianjin sample: usable hardness: 7.0~8.0 CaO content (%): 0.08% Processing services: open book Silica content (%): 32%~42% proportion: 4.4~4.8g/cubic......