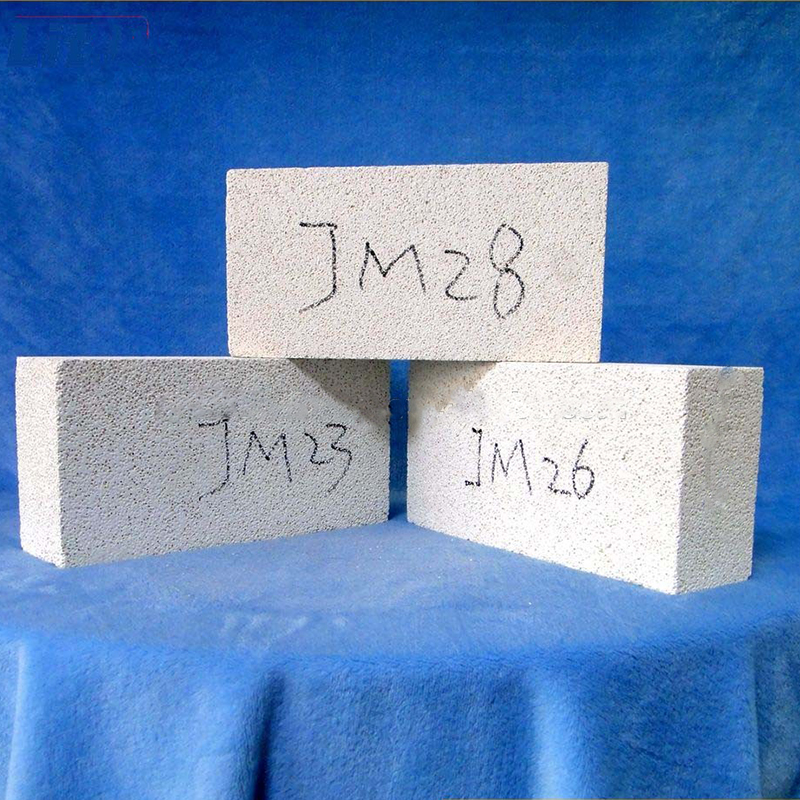

Sintered Mullite Insulation Refractory Brick Lightweight Refractory Brick JM-23

- $0.40 /piece

- 1 piece

- Henan Hongtai Kiln Refractory Co., Ltd.

- Henan, China

- Ms Hongtai Refractory

Product Detail

| Origin: | Henan, China | feature: | refractory |

| Certificate: | International Organization for Standardization | Silicon carbide content (%): | 0.1~1.4% |

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram | Al2O3 content (%): | 38%-75% |

| type: | factory | color: | white |

| sample: | free of charge | CrO content (%): | 0.1~0.3%MAX |

| brand: | Hongtai | Bulk density: | 0.6~1.3g/cm3 |

| Silica content (%): | 15%~45% | Mullite Brick Shape: | brick |

| Material: | Mullite | product name: | mullite brick |

| Mullite brick size: | 230mm*114mm*75mm | Refractoriness (degrees): | Ordinary (1580° |

| CaO content (%): | 0.34% | application: | industrial furnace |

| Supply capacity: | 1000 tons of mullite bricks per month | port: | Tianjin, Qingdao, Lianyungang, Shanghai, Ningbo |

| MgO content (%): | 0.05% max | shape: | brick |

| Packaging Details: | Standard export wooden pallet with cardboard and PET strap, 10 bricks in 1 carton, 48 cartons in 1 pallet. | model: | mullite brick |

Sintered Mullite Insulation Refractory Brick Lightweight Refractory Brick JM-23

Lightweight brick is a high-quality refractory insulation material with light weight, low thermal conductivity, heat insulation and high compressive strength for high-temperature furnaces. Lightweight bricks are mainly used for hot blast stove top, blast furnace chimney and bottom, glass furnace regenerator, ceramic high temperature furnace lining, etc.

Lightweight bricks use mullite as the main crystal phase, containing about 65-75% alumina. Mullite insulation bricks have high refractoriness, up to 1790°C. Its apparent initial softening temperature is about 1600-1700°C. Its cold compressive strength is about 70~260MPa.

Mullite insulation bricks are divided into different models such as 1350 light weight bricks, 1450 light weight bricks and 1550 light weight bricks according to different use temperatures, and are divided into light weight mullite bricks and heavy weight mullite bricks according to different bulk density.

Lightweight brick is a high-quality high-temperature resistant material with the following excellent characteristics

Performance:

Performance:

Low thermal conductivity and low heat capacity

High purity and low impurity content

Excellent high temperature strength

good thermal shock resistance

low expansion coefficient

Strong acid and alkali corrosion resistance

Features of lightweight mullite insulation bricks:

1. Excellent compressive strength

2. Excellent thermal stability

3. Low thermal conductivity

4. Low heat storage

5. High aluminum, low iron and alkali flux content

6. Accurate size

7. Design packaging

Sintered Mullite Insulation Refractory Brick Lightweight Refractory Brick JM-23

| item/index | HT23 | HT26 | HT28 | HT30 | HT32 | |

| Alumina% | 37 | 54 | 64 | 72 | 77 | |

| Ferric oxide% | 1.0 | 0.9 | 0.8 | 0.7 | 0.5 | |

|

Thermal conductivity (w/m*k) |

400°C | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

| 600°C | 0.16 | 0.29 | 0.34 | 0.43 | 0.5 | |

| 800℃ | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

| 1000℃ | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

| Grading temperature (°C) | 1260 | 1430 | 1540 | 1650 | 1760 | |

| Thermal expansion 1000℃ (%) | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | |

| Bulk density (g/cm3) | 0.55-0.62 | 0.78-0.8 | 0.88 | 1.03 | 1.25 | |

| Cold compressive strength (Mpa) | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 | |

| Modulus of rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

| Reheat linear change (%)

CT-30℃*8H |

1230°C

-0.5 |

1400°C

-0.5 |

1510°C

-0.5 |

1620°C

-0.9 |

1730°C

-0.9 |

|

Common Size of Lightweight Bricks

| size | ||

| Length x width x height (mm) | Length × width × height / hour (mm) | Length × width × height / hour (mm) |

| 230×114×65 | 230×614×64 | 250×640×64 |

| 230×114×76 | 230×614×76 | |

| Other sizes according to customer requirements | ||

Power Industry

Power Industrypetrochemical industry

Metallurgical industry

Kiln insulation

other insulation

Recommended for primary hot face refractory lining or for use in furnaces, kilns, flues, refining vessels and heaters, regenerators, gas generators and primary, soaking pits, stress relief furnaces, reaction chambers and other refractories of similar high temperature Spare insulation temperature industrial equipment behind the material.

Sintered Mullite Insulation Refractory Brick Lightweight Refractory Brick JM-23

Package:

Standard export wooden pallet with cardboard and PET strap, 10 bricks in 1 carton, 48 cartons in 1 pallet.

1. Strong packaging will protect the goods from any possible damage during transportation.

2. Sturdy packing and integral packing can prevent the case from vibrating and shaking.

3. We must take the necessary precautions so that the packaging can protect the goods from theft or rain.

4. We can confirm that we have taken every possible precaution to ensure that our products reach our customers all over the world in the best condition.

shipping:

By ship or train from any port in China, samples can be delivered by international express.

Delivery: 15-30 working days for large quantity. We will arrange shipment as soon as possible. Of course, if it is a customized product, the delivery time will be delayed.

Sample: usually by EMS, DHL, UPS, TNT, FedEx. whatever you like. Bulk order: usually by sea.

Payment method: T/T, letter of credit at sight is acceptable. The specific terms are determined according to the quantity of goods, etc.

Your inquiries about our products and prices will be responded within 24 hours.

exit:

Our products have been exported to many countries: Australia, Chile, the United States, Russia, the United Kingdom, Indonesia, etc., and the good quality has been recognized by customers.

about Us

1. Strong professionalism:

Our company has thirty years of experience in the production of refractory products. Our managers will supervise the production materials, process control, quality supervision and package delivery of various refractory materials, and ensure that the products are 100% qualified.

2. Annual supply:

Our company has passed ISO9001 quality management system certification and SGS certification. The annual supply of shaped and unshaped refractory products is 28,800-35,000 tons.

3. Export experience:

Now we have gained a global sales network covering Taiwan, Russia, Korea, Vietnam, Pakistan, Bulgaria, France, India, Congo, Angola, South Africa and so on.

4. Production equipment:

Production and testing equipment are new and complete, automatic or semi-automatic. These modern facilities and equipment provide a good technical guarantee for production and testing.

5. Testing equipment:

Our company's testing equipment is as follows:

High temperature RUL tester

Bulk Density Meter

pressure tester

Fire resistance tester

Related Products

-

BN boron nitride coating for casting materials, aluminum casting coating, die-casting release coating

Product Description Boron nitride coating is a non-toxic, non-polluting and environmentally friendly material that is non-stick and does not penetrate molten metal. It can fully protect the surface of refractory containers that are in direct contact with molten metal and slag, greatly extending the.... -

200 mesh bauxite powder for high temperature kiln in refractory production

Brand Name: Dongtian sample: free size: Size customization Bulk Density: >3.0 MgO content (%): 0.1 Sales Unit: Single item shape: powder Origin: Henan, China Iron Oxide:... -

Good impact resistance cordierite mullite ceramic tube refractory ceramic tube

Place of origin: Jiangsu, China Packaging details: wooden box or carton Refractory degree (degree): Ordinary (1580° Material: cordierite mullite Al2O3 content (%): 48.94 model: HKCD63 Silica content (%): 41.62 Mailing method: DHL, Fedex, UPS or others Key words: Cordierite mullite ceramic tube...... -

China Made Fire Resistant Insulation Material Vermiculite Fire Resistant Insulation Board Vermiculite Board

Packaging details: Fumigated wooden pallet with exterior stretch film and steel foot straps. Refractory degree (degree): Ordinary (1580° brand: cloud field Fire resistance temperature: 1150℃ Silicon carbide content (%): ~ model: vermiculite slab CaO content (%): ~ Supply capacity: Daily output...... -

Low price refractory clay bricks refractory bricks refractory heating furnace boiler kiln industry refractory materials

Supply capacity: 3000 tons of refractory bricks per month color: yellow Operating temperature: 1250-1350 size: client needs Packaging details: 1.International standard airworthy export packaging. 2. Wooden pallets. 3. Wooden/bamboo box (box). 4. Further packaging information will be based on...... -

Silicon Carbide Ceramic Silicon Nitride Si3N4/Sialon Riser Tube for Aluminum Casting

Material: Silicon carbide (SiC) CaO content (%): 0.01 Thermal Conductivity: 0.08W/(meter*K) Refractory degree (degree): Ordinary (1580° Packaging details: The silicon carbide rod has bubble paper inside and a wooden box outside. Moh's hardness: 80-90HRA Magnesium oxide content (%): 0.01 model:...... -

Refractory Bricks Clay Bricks BBQ Pit Price for Glass Oven and Pizza Oven

application: Insulation, fire-resistant lining Ferric oxide%: Maximum 2.5 Load softening temperature (0.2MPa)℃: 1350 minutes Certificate: ISO BV Refractory degree (degree): Ordinary (1580° Bulk density g/cm3: 2.3-2.4kg/cubic meter Al2O3 content (%): 38-42% Silica content (%): 50%~65% port: Qingdao,.... -

230x114x65MM size refractory interlocking clay refractory bricks for kiln

brand: Lecter High temperature cone equivalent Orton cone: 31-32 Package preview: Al2O3 content (%): 36.2 Titanium dioxide(%): 3 Bulk density (kg/m3): 2100-2200 port: Qingdao Na2O+K2O+Li2O(%): 0.5 Material: flint clay Apparent porosity(%): 22-24 Refractoriness (degrees): Ordinary (1580° Supply...... -

High quality lightweight heat insulating refractory bricks jm 23/26/28/30 heat insulating refractory bricks

color: white Operating temperature: 1260 degrees Celsius Aluminum oxide: 35%~40% CaO content (%): 0.01 port: Qingdao Port, Lianyungang application: industrial furnace Material: Mullite Magnesium oxide content (%): 0 shape: brick brand: Shuo Jin Cr2O content (%): 0 payment terms: L/C, Western Union,.... -

Refractory arch brick for pizza oven

Certificate: ISO9001:2000 Cr2O content (%): - shape: brick size: 230x116x65/75 mm Silicon carbide content (%): - model: SK34 Refractoriness (degrees): Ordinary (1580° Material: refractory clay Supply capacity: 5000 tons per month CaO content (%): - Origin: Shandong Province, China Silica content......