SK 32,34 Clay Arched Refractory Bricks for Wood Stoves

- $0.70 / >=20 pieces

- 20 pieces

- Jiangsu Cera Thermal Technology Co., Ltd.

- Jiangsu, China

- Ms Crystal Yu

Product Detail

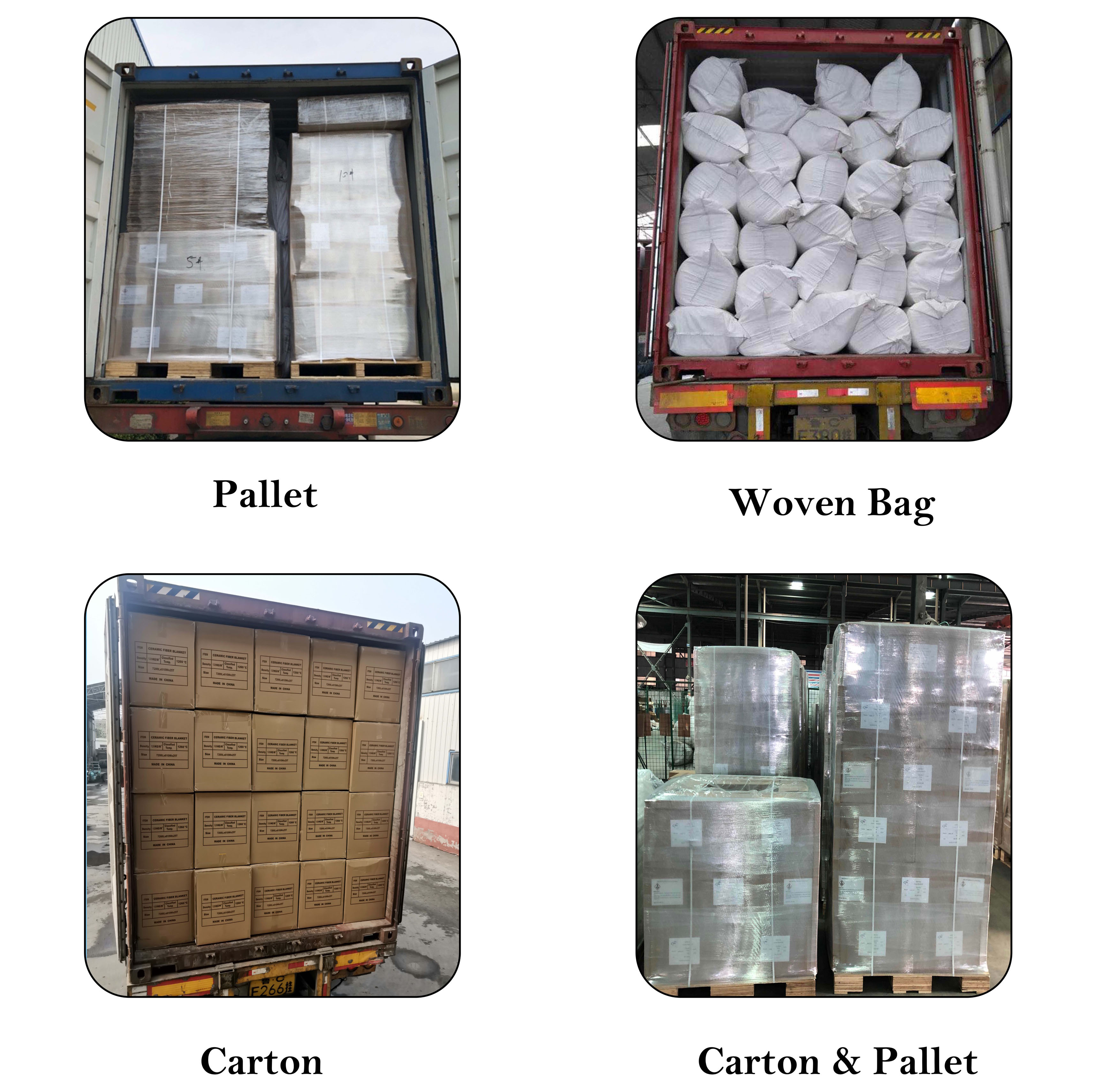

| Supply capacity: | 60000 pieces per month | Packaging Details: | Clay Brick Tray |

| color: | yellow | MgO content (%): | 0 |

| Silica content (%): | uncertain | CaO content (%): | 0 |

| Silicon carbide content (%): | 0 | Package preview: | |

| CrO content (%): | 0 | port: | Shanghai/Qingdao Port |

| Refractoriness (degrees): | 1770°< refractoriness< 2000° | Ferric oxide: | 1.8% |

| Load refractoriness ℃: | 1250 | shape: | brick |

| Refractoriness °C) ≥: | 1670 | brand: | ceramic technology |

| Processing services: | Bending, punching, cutting, forming | Material: | clay brick |

| Alumina: | 45% | Cold compressive strength, MPa≥: | 15 |

| Linear change (%), ℃x2h: | -0.5~0(1350℃) | Al2O3 content (%): | 45% |

| payment terms: | L/C, T/T | model: | CT-SK 32 |

| Porosity%: | 26 | Apparent porosity%: | 16-22 |

| Origin: | Jiangsu, China |

SK 32,34 Clay Arched Refractory Bricks for Wood Stoves

Specification:

Refractory brick manufacturers refractory mud / high alumina

Al2O3:38-75% Size:230*114*65/75mm

Refractory brick is a dense shaped refractory material with high refractoriness and mechanical

Refractory bricks are essential materials for high temperature conditions, mainly used in industrial furnaces and thermal equipment.

Refractory bricks are widely used, mainly in metallurgy, construction (cement and glass), petroleum, chemical industry, electric power and machinery manufacturing.

| product | unit | clay brick | High alumina brick |

||||

| SK32 | SK34 | SK35 | SK36 | SK37 | SK38 | ||

| Al2O3 ≥ | % | 38 | 42 | 48 years old | 55 | 65 | 75 |

| Refractoriness≥ |

℃ | 1670 | 1730 | 1750 | 1770 | 1790 | 1790 |

| Load refractoriness, 0.2MPa ≥ |

℃ | 1250 | 1300 | 1420 | 1470 | 1500 | 1520 |

| Linear change (%) | ℃x2h |

1350 (-0.5-0) |

1350 (-0.5~0) |

1450 (-0.~+0.1) |

1500 (-0.~+0.1) |

1500 (-0.~+0.1) |

1500 (-0.~+0.1) |

| Porosity≤ | % | 26 | 26 | twenty two | twenty two | twenty three | twenty three |

| Cold compressive strength≥ | MPa | 15 | 20 | 39.2 | 44.1 | 49 | 53.9 |

Jiangsu Sairui Thermal Technology Co., Ltd. was formerly known as Nanjing Sairui Material Technology Co., Ltd. The company's main business includes refractory material production, high-temperature thermal furnace lining design and construction, kiln equipment, research and development, etc. Development and sales of refractory materials. Through years of cooperation with Morgan Thermal Ceramics in the UK, we have accumulated rich experience in a large number of engineering projects. We can provide customers with various high-quality

According to the actual working conditions and requirements of each customer, we provide professional and customized products and engineering services to meet customers' increasing energy-saving needs.

Our tenet is: quality and reputation are fundamental, technology and service are life.

- 2002 Established Nanjing Sairui Material Technology Co., Ltd.

- In 2005, the Nanjing workshop was established.

- 2009 Established Suzhou SLMC Thermal Insulation Material Co., Ltd.

- 2010 Shandong Zibo Baoyang Refractory Fiber Co., Ltd. was established

- 2013 Established Thermaltec Insulation (Zhejiang) Company Limited.

- 2013 Jiangsu Sairui Thermal Energy Technology Co., Ltd. was established

We have obtained GB/T 19001-2008/ISO 9001:2008 quality system certification.

High-tech enterprise declaration.

1. How to control your quality?

A1: For each order, Jiangsu Cera Tec has a completequality control system,We have a professional testing team

For chemical and physical properties of the product.

2. What is your delivery time?

A2: Usually it takes about10-15 daysAfter receiving the PO.

3. What's the MOQ for an order?

A3:not limited, we can provide the best suggestion and solution according to your situation..

4. Do you provide free samples?

A4: Of course, we can providefree samplefor you to test.

5. Can we visit your company?

A5: Yes, welcome to visit our company and taste Chinese food.

6. Is there a video of ceramic fiberboard catching fire? ?

A6: We have a special videofire test, the spray gun used is 1300°C.

Related Products

-

BN boron nitride coating for casting materials, aluminum casting coating, die-casting release coating

Product Description Boron nitride coating is a non-toxic, non-polluting and environmentally friendly material that is non-stick and does not penetrate molten metal. It can fully protect the surface of refractory containers that are in direct contact with molten metal and slag, greatly extending the.... -

200 mesh bauxite powder for high temperature kiln in refractory production

Brand Name: Dongtian sample: free size: Size customization Bulk Density: >3.0 MgO content (%): 0.1 Sales Unit: Single item shape: powder Origin: Henan, China Iron Oxide:... -

Good impact resistance cordierite mullite ceramic tube refractory ceramic tube

Place of origin: Jiangsu, China Packaging details: wooden box or carton Refractory degree (degree): Ordinary (1580° Material: cordierite mullite Al2O3 content (%): 48.94 model: HKCD63 Silica content (%): 41.62 Mailing method: DHL, Fedex, UPS or others Key words: Cordierite mullite ceramic tube...... -

China Made Fire Resistant Insulation Material Vermiculite Fire Resistant Insulation Board Vermiculite Board

Packaging details: Fumigated wooden pallet with exterior stretch film and steel foot straps. Refractory degree (degree): Ordinary (1580° brand: cloud field Fire resistance temperature: 1150℃ Silicon carbide content (%): ~ model: vermiculite slab CaO content (%): ~ Supply capacity: Daily output...... -

Low price refractory clay bricks refractory bricks refractory heating furnace boiler kiln industry refractory materials

Supply capacity: 3000 tons of refractory bricks per month color: yellow Operating temperature: 1250-1350 size: client needs Packaging details: 1.International standard airworthy export packaging. 2. Wooden pallets. 3. Wooden/bamboo box (box). 4. Further packaging information will be based on...... -

Silicon Carbide Ceramic Silicon Nitride Si3N4/Sialon Riser Tube for Aluminum Casting

Material: Silicon carbide (SiC) CaO content (%): 0.01 Thermal Conductivity: 0.08W/(meter*K) Refractory degree (degree): Ordinary (1580° Packaging details: The silicon carbide rod has bubble paper inside and a wooden box outside. Moh's hardness: 80-90HRA Magnesium oxide content (%): 0.01 model:...... -

Refractory Bricks Clay Bricks BBQ Pit Price for Glass Oven and Pizza Oven

application: Insulation, fire-resistant lining Ferric oxide%: Maximum 2.5 Load softening temperature (0.2MPa)℃: 1350 minutes Certificate: ISO BV Refractory degree (degree): Ordinary (1580° Bulk density g/cm3: 2.3-2.4kg/cubic meter Al2O3 content (%): 38-42% Silica content (%): 50%~65% port: Qingdao,.... -

230x114x65MM size refractory interlocking clay refractory bricks for kiln

brand: Lecter High temperature cone equivalent Orton cone: 31-32 Package preview: Al2O3 content (%): 36.2 Titanium dioxide(%): 3 Bulk density (kg/m3): 2100-2200 port: Qingdao Na2O+K2O+Li2O(%): 0.5 Material: flint clay Apparent porosity(%): 22-24 Refractoriness (degrees): Ordinary (1580° Supply...... -

High quality lightweight heat insulating refractory bricks jm 23/26/28/30 heat insulating refractory bricks

color: white Operating temperature: 1260 degrees Celsius Aluminum oxide: 35%~40% CaO content (%): 0.01 port: Qingdao Port, Lianyungang application: industrial furnace Material: Mullite Magnesium oxide content (%): 0 shape: brick brand: Shuo Jin Cr2O content (%): 0 payment terms: L/C, Western Union,.... -

Refractory arch brick for pizza oven

Certificate: ISO9001:2000 Cr2O content (%): - shape: brick size: 230x116x65/75 mm Silicon carbide content (%): - model: SK34 Refractoriness (degrees): Ordinary (1580° Material: refractory clay Supply capacity: 5000 tons per month CaO content (%): - Origin: Shandong Province, China Silica content......