Buy 42% Al2O3 SK34 refractory clay bricks, refractory bricks for pizza oven/stove/fireplace

- $0.30 /piece

- 1 piece

- Gongyi City Tonten Abrasive Co., Ltd.

- Henan, China

- Ms Maggie Li

Product Detail

| product name: | 42% Al2O3 refractory bricks, refractory bricks for pizza oven/stove/fireplace | CaO content (%): | a little |

| CrO content (%): | a little | Al2O3 content (%): | 30% ~ 48% |

| Silicon carbide content (%): | a little | application: | Refractory bricks for pizza oven/stove/fireplace |

| brand: | Tongteng refractory brick | Packaging Details: | Packaging information of our 42% clay bricks: 1. On wooden pallet with plastic cover; Wooden pallet size: 1000*1000*1000mm Loading capacity per pallet: 1.6-2.0 tons 2. According to customer requirements |

| brand: | Tong Teng | shape: | 230*114*65mm or customized, brick |

| Supply capacity: | 2000 metric tons per month of 42% refractory clay bricks | Material: | Alumina block |

| Origin: | Henan, China | Ferric oxide: | 4% |

| payment terms: | Western Union, D/P, D/A, T/T, MoneyGram | color: | nature |

| Alumina: | 48% ~ 30% | raw material: | High alumina bauxite |

| MgO content (%): | a little | Silica content (%): | 65% ~ 50% |

| model: | 42% refractory brick | sample: | usable |

| port: | Tianjin/Qingdao/Lianyungang/Guangzhou/Ningbo | Refractoriness (degrees): | Ordinary (1580° |

| Refractoriness: | 1580 degrees minimum |

Buy 42% Al2O3 SK34 refractory clay bricks, refractory bricks for pizza oven/stove/fireplace

Buy 42% Al2O3 SK34 Refractory Clay Bricks, Refractory Bricks for Pizza Oven/Stove/Fireplace Description:

What are 42% clay bricks?

1. Clay refractory brick is a refractory material with high refractoriness.

2. Al2O3 content of 42% clay refractory bricks: more than 30%.

3. The refractoriness of 42% clay bricks is generally above 1580°C, which increases with the increase of Al2O3 content.

What are the physical and chemical indicators of our 42% clay bricks?

| thing | TONTEN 42% clay refractory brick | ||

| product |

SK30 42% refractory clay brick |

SK32 42% refractory clay brick |

SK34 42% refractory clay brick |

| Aluminum oxide | 33% | 38% | 38-45% |

| Ferric oxide | 3% | 3% | 3% |

| Bulk density g/cm3 | ≥1.9~2.0 | ≥2.1 | ≥2.15 |

| Refractoriness °C | ≥1670 | ≥1700 | ≥1730 |

| Apparent porosity % | ≤26% | ≤26% | ≤22% |

| Cold compressive strength MPa | ≥25 | ≥30 | ≥35 |

| Load refractoriness (0.2MPa) °C | ≥1230℃ | ≥1250℃ | ≥1280℃ |

| Reheat linear change (1500℃, 2h) | -0.5 ~ 0 | -0.5 ~ 0 | -0.3 ~ 0 |

What are the shapes and sizes of our clay refractory bricks?

| straight | to split | arch | wedge | watt | other |

| L*W*H(mm) | L*W*H(mm) | L*W*H(mm) | L*W*H(mm) | L*W*H(mm) | L*W*H(mm) |

|

230×114×65 230×114×75 |

230×114×25 230×114×32 230×114×37 230×114×50 |

230×114×65/45 230×114×65/55 230×114×75/45 230×114×75/55 230×114×75/65 |

230×114×65/45 230×114×65/55 220×114×75/45 220×114×75/55 220×114×75/65 |

230×230×38 230×230×50 230×230×65 230×230×75 |

key brick, oblique bricks, Soap, inspector, neck, Taper |

|

Comment: |

Other shapes are customized according to your drawings and requirements. | ||||

Advantages of our 42% clay bricks ?

1. High refractoriness.

2. Good peeling resistance and wear resistance.

3. Good corrosion resistance.

4. Good thermal shock resistance.

5. High mechanical strength.

6. Low creep rate at high temperature.

What are the applications of our abrasive 42% refractory clay bricks?

Clay refractory bricks are widely used in blast furnaces, hot blast furnaces, ladle linings, heating furnaces, cement kilns, tunnel kilns, boilers, coke ovens, carbon furnaces, glass furnaces, steelmaking furnaces and various furnace linings and thermal equipment, etc.

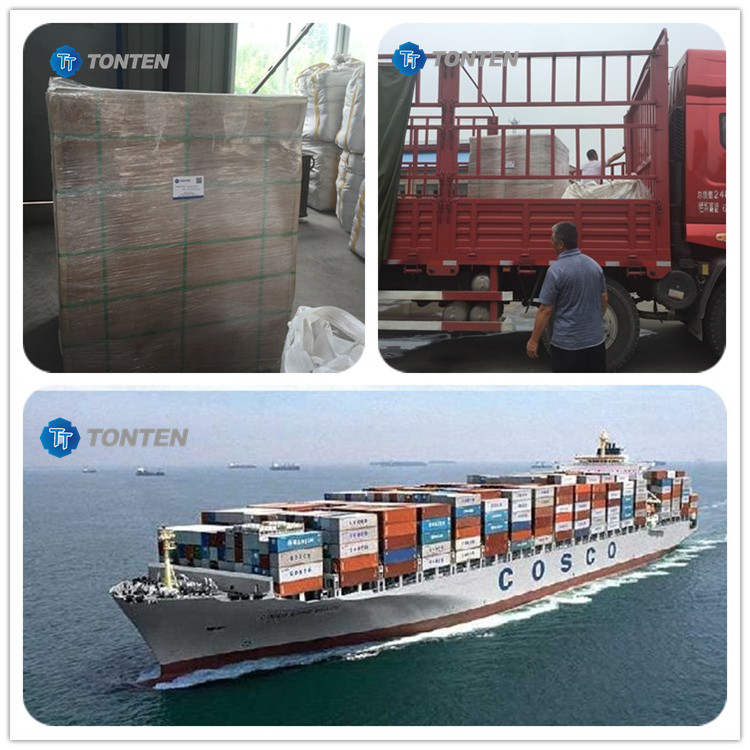

Our 42% fireclay brick packaging information:

- on wooden pallets with plastic covers;

Wooden pallet size: 1000*1000*1000mm Load capacity per pallet: 1.6-2.0 tons - According to customer requirements

Lead Time of Our Abrasive 42% Fire Clay Bricks:

- 3-7 days for sample order;

- 5-25 days after receiving payment for bulk order.

Related Products

-

BN boron nitride coating for casting materials, aluminum casting coating, die-casting release coating

Product Description Boron nitride coating is a non-toxic, non-polluting and environmentally friendly material that is non-stick and does not penetrate molten metal. It can fully protect the surface of refractory containers that are in direct contact with molten metal and slag, greatly extending the.... -

200 mesh bauxite powder for high temperature kiln in refractory production

Brand Name: Dongtian sample: free size: Size customization Bulk Density: >3.0 MgO content (%): 0.1 Sales Unit: Single item shape: powder Origin: Henan, China Iron Oxide:... -

Good impact resistance cordierite mullite ceramic tube refractory ceramic tube

Place of origin: Jiangsu, China Packaging details: wooden box or carton Refractory degree (degree): Ordinary (1580° Material: cordierite mullite Al2O3 content (%): 48.94 model: HKCD63 Silica content (%): 41.62 Mailing method: DHL, Fedex, UPS or others Key words: Cordierite mullite ceramic tube...... -

China Made Fire Resistant Insulation Material Vermiculite Fire Resistant Insulation Board Vermiculite Board

Packaging details: Fumigated wooden pallet with exterior stretch film and steel foot straps. Refractory degree (degree): Ordinary (1580° brand: cloud field Fire resistance temperature: 1150℃ Silicon carbide content (%): ~ model: vermiculite slab CaO content (%): ~ Supply capacity: Daily output...... -

Low price refractory clay bricks refractory bricks refractory heating furnace boiler kiln industry refractory materials

Supply capacity: 3000 tons of refractory bricks per month color: yellow Operating temperature: 1250-1350 size: client needs Packaging details: 1.International standard airworthy export packaging. 2. Wooden pallets. 3. Wooden/bamboo box (box). 4. Further packaging information will be based on...... -

Silicon Carbide Ceramic Silicon Nitride Si3N4/Sialon Riser Tube for Aluminum Casting

Material: Silicon carbide (SiC) CaO content (%): 0.01 Thermal Conductivity: 0.08W/(meter*K) Refractory degree (degree): Ordinary (1580° Packaging details: The silicon carbide rod has bubble paper inside and a wooden box outside. Moh's hardness: 80-90HRA Magnesium oxide content (%): 0.01 model:...... -

Refractory Bricks Clay Bricks BBQ Pit Price for Glass Oven and Pizza Oven

application: Insulation, fire-resistant lining Ferric oxide%: Maximum 2.5 Load softening temperature (0.2MPa)℃: 1350 minutes Certificate: ISO BV Refractory degree (degree): Ordinary (1580° Bulk density g/cm3: 2.3-2.4kg/cubic meter Al2O3 content (%): 38-42% Silica content (%): 50%~65% port: Qingdao,.... -

230x114x65MM size refractory interlocking clay refractory bricks for kiln

brand: Lecter High temperature cone equivalent Orton cone: 31-32 Package preview: Al2O3 content (%): 36.2 Titanium dioxide(%): 3 Bulk density (kg/m3): 2100-2200 port: Qingdao Na2O+K2O+Li2O(%): 0.5 Material: flint clay Apparent porosity(%): 22-24 Refractoriness (degrees): Ordinary (1580° Supply...... -

High quality lightweight heat insulating refractory bricks jm 23/26/28/30 heat insulating refractory bricks

color: white Operating temperature: 1260 degrees Celsius Aluminum oxide: 35%~40% CaO content (%): 0.01 port: Qingdao Port, Lianyungang application: industrial furnace Material: Mullite Magnesium oxide content (%): 0 shape: brick brand: Shuo Jin Cr2O content (%): 0 payment terms: L/C, Western Union,.... -

Refractory arch brick for pizza oven

Certificate: ISO9001:2000 Cr2O content (%): - shape: brick size: 230x116x65/75 mm Silicon carbide content (%): - model: SK34 Refractoriness (degrees): Ordinary (1580° Material: refractory clay Supply capacity: 5000 tons per month CaO content (%): - Origin: Shandong Province, China Silica content......