Crystal Clear Factory Price Deep Cast Resin Wood Clear Resin Epoxy Countertop

-

$4.40 / 1 - 999 kilograms

$4.13 / 1000 - 2999 kilograms

$3.90 / 3000 - 9999 kilograms

$3.60 / >=10000 kilograms - 1 kilogram

- Guangdong Jinhua New Materials Technology Co., Ltd.

- Guangdong, China

- Ms Coco Dai

Product Detail

| Classification: | two-component adhesive | main ingreadient: | epoxy resin |

| Feature D: | good resistance to yellowing | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Feature one: | Automatic defoaming | brand: | Jinhua |

| Function B: | high transparency | usage: | Construction, Fibers and Clothing, Footwear and Leather, Packaging, Transport, Carpentry |

| CAS number: | 25068-38-6 | Shelf life: | 6 months |

| Other names: | epoxy wood countertop glue | IF: | not any |

| type: | epoxy resin | Function C: | easy to use |

| Packaging Details: | 5kg per bottle; 20kg per carton 20kg per barrel 200kg per barrel Delivery time: 3 days | port: | Shenzhen Port, China |

| model: | 318AB-7T | Key words: | epoxy resin |

| Certificate: | ROHS, REACH, PAHS, ASTM, EN-71 | Supply capacity: | 10 tons per day |

| The mixing ratio: | A:B=3:1 | place of origin; place of origin: | Guangdong, China |

| color: | to clear | Package preview: |

REACH, PAHS, ASTM, SA8000, EN-71 Certificates! ! !

3. to youHigh quality and high value products, our advanced technology makes us a leader in related fields.

4. Always maintain the conceptdevelop.

Product Description

Crystal Epoxy River Table Casting Table This thick cast or known as deep cast clear epoxy is a "top of the line" clear high performance epoxy resin system that can be used in many casting applications including:- Jewelry, Furniture, Promotional Products, Trophies , floral displays, artwork, model making, set design, "one-off" niche products, and more. A premium all-purpose thick cast or what we also call deep cast clear epoxy for all those heavy use jobs - and it doesn't contain any solvents!

Properties before hardening

part | 318A-7T | 312A-7T |

color | transparent | transparent |

proportion | 1.15 | 0.96 |

Viscosity (25°C) | 2000-4000CPS | 80 max per second |

The mixing ratio | A: B = 100:33 (weight ratio) | A: B = 100:33 (weight ratio) |

hardening condition | 25℃×8H to 10H or 55℃×1.5H (2g) | 25℃×8H to 10H or 55℃×1.5H (2g) |

available time | 25℃×40min (100g) | 25℃×40min (100g) |

Operation

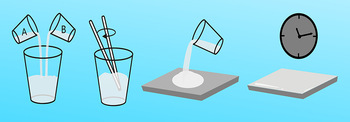

1. Weigh the glues A and B according to the given weight ratio and put them into the prepared and cleaned container, pour the mixture clockwise on the wall of the container and mix well, leave it for 3-5 minutes before use.

2. Take the glue according to the use time and mixing amount to avoid waste. When the temperature is lower than 15°C, please heat glue A to 30°C before mixing with glue B (glue A will thicken at low temperature); the glue must be covered after use to avoid repelling caused by moisture absorption.

3. When the relative humidity is higher than 85%, the surface of the cured mixture will absorb moisture in the air and form a layer of white mist on the surface. Therefore, when the relative humidity is higher than 85%, it is not suitable for room temperature curing. It is recommended to use heat curing.

Related Products

-

Liquid Epoxy Resin Raw Material Price Industrial Resin Epoxy Resin Curing Agent Chemicals

Viscosity: Resin 1600cps Curing agent 100cps IF: C15H16O2C2H7ONC3H5OCl Package preview: Origin: Guangdong, China EINECS number: 230-391-5 Classification: Two-component adhesive Minimum order quantity: 20kg color: transparent model: YD-128 Chemical Abstracts Service number: 7085-85-0 usage:...... -

High Penetration Clear Epoxy Resin for Outdoor Gravel Driveway Epoxy Aggregate Paving Stone Floor Coating Resin 20kg Kit

Shelf life: 6 months Classification: Two-component adhesive Original Equipment Manufacturers: Provide OEM/ODM/label customization services Packaging Details: 15KG/3 gallon kit; 1.5 gallon; 5kg, 20kg kit; 25kg; 15 gallon; 200kg. Support OEM/ODM customization. Origin: Guangdong, China usage: Suitable.... -

Recina Epoxica Para Pisos Epoxy AB Glue Self-Leveling Floor Kit for Concrete and Cement Floor Coating

Product Category: 2 parts Chemical Abstracts Service number: 38891-59-7 Place of origin: Guangdong, China port: Shenzhen feature: Good fluidity, low viscosity, bright surface Performance: No yellowing Supply capacity: 1000 tons per month color: transparent Classification: Two-component adhesive...... -

Crystal AB glue epoxy resin/transparent liquid epoxy resin

The mixing ratio: A:B=3:1 model: 318AB-9 Feature 1: Automatic defoaming Origin: Guangdong, China type: epoxy resin Packaging Details: 5kg per bottle; 20kg/carton 20kg/barrel 200kg/barrel Delivery time: 3 days color: to clear usage: Construction, Fibers and Clothing, Footwear and Leather, Packaging,.... -

Crystal Clear/Epoxy-Resin-Table-Top Deep Casting Epoxy Resin Suppliers

payment terms: L/C, Western Union, D/P, T/T, Paypal The mixing ratio: A:B=3:1 EINECS number: 231-072-3 Other names: epoxy resin CAS number: 38891-59-7 Material: epoxy resin Package preview: IF: C15H16O2C2H7ONC3H5OCl Classification: two-component adhesive type: two components model: 312AB-6-N usage:.... -

Transparent 3d epoxy floor paint transparent epoxy resin liquid resin

The mixing ratio: A:B=3:1 payment terms: Western Union, T/T, MoneyGram main ingreadient: epoxy resin usage: Construction, Fibers and Clothing, Woodworking brand: De Jianbang Supply capacity: 100,000 kg per month IF: mixture color: Transparent liquid port: Qingdao/Shanghai/Yiwu/Shenzhen CAS number:..... -

Holographic Glitter Floor Coating Epoxy Glitter Floor

EINECS number: other Classification: two-component adhesive brand: Mountain bike JZJ product name: Holographic Glitter Floor Coating Epoxy Glitter Floor CAS number: 61788-97-4 payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram color: to clear usage: Construction, transportation, floor...... -

Rhinestone crafts multi-purpose strong glue cloth metal stone manicure wood glass B7000 jewelry bead glue

Package preview: MOQ: 3 payment terms: Western Union, T/T Origin: China sample: available delivery time: within 5 working days OEM/Design Manufacturer: OEM ODM private label model: M42 main ingreadient: acrylic fiber product name: B7000 glue Pay: Trade Assurance. Western Union. TT Packaging...... -

Strong glue ab glue transparent liquid crystal epoxy resin good quality and good price

port: Hong Kong port usage: put up color: Colorless translucent/colorless transparent Density (g/m3): 1.07+0.05/0.95+0.03 type: Resin 312A-H3/curing agent 312B-H3, AB glue Other names: Adhesive IF: [CH(CH2Cl)CH2O]n Classification: other adhesives model: 312AB-H3 brand: benu Mixing ratio (weight...... -

Spray Foam Insulation Polyurethane Foam Kit (650-215 Board Feet) Izotup 200 Quick Rise (QR) with Mask Cylindrical Tube Material

payment terms: wire transfer usage: Construction, Fibers and Clothing, Footwear and Leather, Packaging, Transport, Carpentry Name: Spray Polyurethane Foam Kit Foam Type: Obturator type: closed cell foam size: 41 lbs / 16" x 16" x 9" / 215 BdFt Classification: two-component adhesive EINECS number:......