Microsilica fume in Philippine construction

- $0.12 / >=10 kilograms

- 10 kilograms

- Quanzhou Winitoor Import & Export Co., Ltd.

- Fujian, China

- Ms Winnie Chen

Product Detail

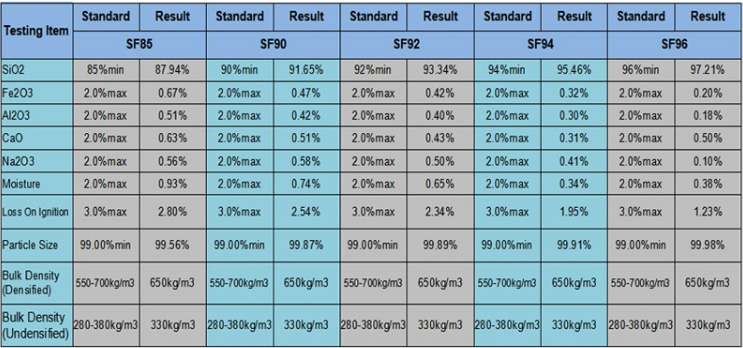

| quality: | SGS testing | application: | refractory |

| Chemical Abstracts Service number: | 69012-64-2 | brand: | Venetour |

| Magnesium oxide content (%): | 0.55% | Silica content (%): | 91.65% |

| appearance: | power particles | color: | White&light gray&dark gray |

| P2O5 content (%): | 0.789% | port: | Xiamen Port or upon request |

| purity: | 5N | Packaging details: | Packaging details: 1.500kg/1000kg jumbo bag (UV protected) with wooden pallet 2.. small bags (20kg, 25kg per bag) 3. As per customer requirements |

| Certificate: | ISO9001 | Titanium dioxide%: | <0.001 |

| grade: | Silica Micro-400 | payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| type: | Silica powder | model: | WT92D |

| Place of origin: | China | CaO content (%): | 0.51% |

| Al2O3 content (%): | 0.42% | usage: | cement concrete refractory materials |

| Package preview: | Fe2O3 content (%): | 0.47% | |

| Name: | High quality silica powder | The fluidity of our silica powder: | Good flowing undensified silica |

| Supply capacity: | 5000 tons per month |

Microsilicon, also known as silicon powder or microsilicon, is a by-product of the production of silicon metal or ferrosilicon alloys. Silicon metal and alloys are produced in electric furnaces. The raw materials are quartz, coal and wood chips. The fumes from furnace operations are collected and sold as silica fume, which consists primarily of amorphous (non-crystalline) silica (SiO2). ), the average particle size is 0.15~0.20um, the specific surface area is 15000~20000m2/kg, and it has extremely strong surface activity.

1).The appearance is off-white.

2).High resistivity

3).Low penetration rate

4).Excellent resistance to chemical attack by chlorides, acids and sulfates

5).Low chloride ion diffusion

6).Highly active volcanic ash

7).High temperature strength

8).Improve the stability of geothermal environment

1) concrete or shotcrete

• Increase its density and strength, improve its durability,

Impact resistance, corrosion resistance, penetration resistance, frost resistance, etc.

2) Refractory materials and ceramic materials

• Significantly improves its density, strength and high temperature performance.

3) Cement repair products(Mortar and Grout)

• Low permeability, enhanced resistance to chlorides, acids, nitrates and sulfates, etc.

4) Oil well grouting

• Improved durability and compressive strength, reduced permeability, and better control of gas leaks

5) Concrete tiles, roof and wall panels, panels

• Lightweight and improved strength

6) Polymer and rubber products

7) Other applications, such as water glass industry, thermal insulation materials, etc.

Related Products

-

Magic transparent silica sand manufacturing Egyptian craft natural beach silica quartz ordinary silica oxide fine 250 white

Product Description Specification thing value Place of origin Egypt Brand name Silica Sand 100 model Silicon sand 100 type Silicon quartz application Glass grade Silica oxidized microcells-400 SIO2 content (%) (99.50%) (99.30%) (99.20%) Fe2O3 content (%) (0.001) ppm (0.015) ppm (0.025) ppm (0.030)..... -

High purity and dense 92 grade microsilica silica fume for concrete in China 94% ton price

Product Description High quality fumed silica for building concrete Specification thing value Origin China Hebei brand name Weiran Silica content (%) >90% Fe2O3 content (%)... -

Crushed clear glass sand for sandblasting media and crafts

Glass sand, crystal sand, silica sand for swimming pool filtration Glass sand is divided into colored glass sand and transparent glass sand. Glass sand is used for glass surface decoration, such as glass, vases, lampshades, etc. The glass sand is fused with the glass workpiece to form a concave and.... -

High quality silica powder for UHPC at wholesale price

Origin: China application: refractory type: Silica powder Payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Minimum order quantity: 10 tons Product name: Microsilica powder Material: Silica Silica content (%): 95% shape: powdery purity: 95% silica CaO content (%): 1ppm~5ppm grade: Silica..... -

92% Dense Grade Silica China Supplier Wholesale Concrete Microsilica Powder

Free CaO (%): 92% Construction Industry USF 940 > 94% Refractory Materials USF 960 > 96% Building and refractory materials White microsilica powder grade Silica content ZrO2 content SMIC 940 > 92% < 2% SMIC 950 > 93% < 2% SMIC 960 > 94% < 2% SMIC 970 > 95% < 2%... -

China industrial colored sand/glass silica sand is widely used

Al2O3 content (%): Maximum 1.14% purity: 5N Place of origin: Hebei china Silica content (%): 79.8%~98% Machine-made sand type: Machine-made sand Advantage: Very dry, clean and free of impurities payment terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram Supply capacity: 4800 metric tons per month..... -

50-150 micron high-grade electrofusion powder pure fine white quartz silica sand

usage: foundry Key words: fuse Magnesium oxide content (%): 0.55% application: electrode diameter: 10mm-600mm Material: 99.99% pure quartz grade: Silica Micro-400 Fe2O3 content (%): 0.018% brand: frequency shift keying product name: Fused quartz sand for precision casting CaO content (%): 0.09%...... -

Quartz silica sand as raw material for different industries

application: Glass grade: Silica ordinary fine-250 Place of origin: Liaoning, China port: Dalian, China color: white Packaging details: giant bag Minimum order quantity: 1MT Silica content (%): 99% purity: 99% type: Quartz Fe2O3 content (%): 0.018% Supply capacity: Annual output 10,000 tons...... -

Silica Quartz Glass Tube 99.5-99.98% Pure Vision Quartz Tube Crystal Clarity Glass Tube Ultra-Pure Quartz Tube OptiC

grade: Silica ordinary fine-250 Al2O3 content (%): 0.03% Sand type: Machine-made sand Package preview: payment terms: Letter of credit, wire transfer application: Glass model: 2506.1000 P2O5 content (%): millionth size: Customer requirements Packaging details: Bulk/Bulk 1.25 Bag Jumbo Bag port:......