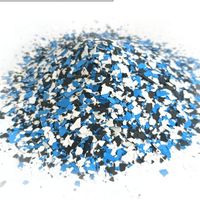

Factory direct sale muscovite flakes ruby green gold brown mica flakes top quality

-

$77.00 / 1 - 49 kilograms

$60.00 / 50 - 99 kilograms

$46.00 / >=100 kilograms - 1 kilogram

- Hebei Ansta Trading Ltd.

- Hebei, China

- Ms Ansta An

Product Detail

| CaO content (%): | 0.02-0.77% | feature: | environmentally friendly |

| Package: | custom | Silica content (%): | 44.00-50.00% |

| usage: | Water Level Indicator/Radar | color: | Ruby/Green/Gold/Brown/Clear |

| MgO content (%): | 0.32-2.00% | brand: | Ansta |

| Name: | Muscovite flakes | Al2O3 content (%): | 20.00-33.00% |

| type: | muscovite | K2O content (%): | 9.00-11.00% |

| Origin: | Hebei china | aspect: | 1#2#3#4#5#, customized |

| application: | fire protection | Fe2O3 content (%): | 2.00-6.00% |

| form: | Hebei | Package preview: | |

| model: | sheet | shape: | round/square/irregular, square |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

muscoviteMuscovite is an important rock-forming mineral that occurs in igneous, metamorphic, and sedimentary rocks. As a natural silica, muscovite is a very special functional filler due to its highly layered structure and purity. Muscovite is chemically inert, resistant to most acids and oxidation, insoluble in water and resistant to high temperatures. It also exhibits excellent electrical insulating properties.

Product Description

Muscovite, whose chemical formula is KAl2(AlSi3O10)(OH)2, is the most common mineral in the mica family. The global consumption of mica is as high as 1 million tons, of which 90% is muscovite. The layered structure is obvious, lighter and softer.

chemical composition:

element | silica | Aluminum oxide | potassium oxide | Na2O | magnesium oxide | Calcium Oxide | Titanium dioxide | Fe2O3 | S+P |

content(%) | 38.0-50.0 | 13.3-32.0 | 2.5-9.8 | 0.6-0.7 | 0.3-5.4 | 0.4-0.6 | 0.3-0.9 | 1.5-5.8 | 0.02 |

Physical properties:

Heat resistance (℃) | Moh's hardness | Density (g/cm3) | Dielectric strength (KV/mm) | Tensile Strength (MPa) | Surface resistivity (Ω) | Melting point (°C) |

650 | 2.5-3 | 2.8-2.9 | 115-140 | 110-145 | 1×1011-12 | 1200 |

customer service

application

The manufacturing process of mica powder has two kinds of dry grinding and wet grinding.We have our own factories to produce these two products.

Dry ground mica powderProduced by physical grinding without altering any of the natural properties of the mica. We use a fully enclosed filling system to ensure the quality of the entire production process. During the screening process, we also use proprietary equipment and technology to ensure uniform particle distribution and stable quality. Due to its superior properties, dry ground muscovite has been widely used in the production of various products including fiber cement building panels/wall panels, plastics, rubber, paints, coatings, welding electrodes, oil drilling and brake pads.

Wet ground mica powderUsing natural mica flakes as raw materials, it is produced through a series of processes such as cleaning, washing, purification, wet grinding, drying, screening, and grading. The unique production process retains the flake structure of mica, so the wet-ground mica has the characteristics of large diameter-thickness ratio, low sand content and iron content, high purity, high whiteness, and high gloss. The unique properties of wet grinding mica make it widely used in paint, coating production, rubber, plastic, ceramics and other industries. It is especially effective for improving the electrical strength, rigidity, and heat resistance of products, reducing molding shrinkage, and reducing costs.

VIEW MORE

Related Products

-

Construction Tools High Quality Epoxy Floor Tools Self-Leveling Paint Spikes Epoxy Floor Paint

Product Description Name spikes Material EVA soft glue size 9#,11#,16# Package carton Nail size 20mm quality high quality net weight 1.6kg Recommended products Factory display Tianjin Zhixiang Technology Co., Ltd. is a subsidiary of Tianjin CFS Co., Ltd. It is a specialized company engaged in the...... -

Wholesale 3-5 mm concrete garage epoxy floor coating resin flakes mica flakes for epoxy floor paint

Material: Raw material mica appearance: Color flakes aspect: 1-8 mm Calcium oxide content (%): 0.02-0.77% Product Name: Mica Sheet Fe2O3 content (%): 2-6% color: Bright silver white color: Multicolor Minimum Order Quantity: 1 kg Origin: Tianjin, China sample: Provide samples SiO2 content (%): 38-50.... -

Mineral muscovite/phlogopite/phlogopite decoration for surface road construction

size: 1-2mm 4-8mm 6-10 mesh 10-20 mesh 20-40 mesh 40-80 mesh CaO content (%): 0.4-0.6% color: Silver white green black blue gray red etc. Place of origin: Hebei china Package preview: K2O content (%): 8.5-9.8% usage: Decoration, floor coating, road construction model: NS-Mica Terms of trade: FOB...... -

Electrical Insulating Mica Tube Muscovite Phlogopite Mica Tube

type: muscovite test method: Strict quality inspection one by one payment terms: Western Union, wire transfer, MoneyGram size: customizable Package preview: Place of origin: China Shanghai Al2O3 content (%): 38.5% product name: Refractory ceramic tube for electric heating application: Welding...... -

Factory direct sales of epoxy materials, various mixed best-selling color mica flakes

port: Any port in China application: coating Minimum order quantity: 100kg appearance: Colorful film CaO content (%): 0.02-0.77% type: muscovite Certificate: ISO9001 Place of origin: Tianjing, China color: Polychromatic Supply capacity: 10,000 kg per week K2O content (%): 0.2-0.5% Magnesium oxide...... -

Muscovite/biotite/sericite/phosphorus mica

Oil absorption: 48-500g/100g Fe2O3 content (%): 2-6% color: gold, silver, red, yellow, blue, black K2O content (%): 9-11% shape: flake, flaky payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Magnesium oxide content (%): 0.3-2% Key words: mica Package preview: origin: Hebei china sample:..... -

China factory epoxy material mica sheet concrete floor design more than 300 different colors free samples

aspect: 1-7/mm Silica content (%): 38-50 Name: Synthetic flaky mica powder sample: free of charge Package: custom packaging type: muscovite size: 1-8 mm product name: Mica slice payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram color: Polychromatic port: any port in China K2O content (%):.... -

High temperature resistant muscovite flakes for low price natural mica paint

weight: 5kg, 500kg, 1000kg or customized Oil absorption: 35-55ml/100g Al2O3 content (%): 13.3-32.0 feature: environmentally friendly payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram color: Clear/Green/Ruby/Brown Name: Muscovite flakes Fe2O3 content (%): 1.5-5.8 port: star port shape:...... -

Wholesale High Quality Resin Epoxy Mica Sheet Vinyl Sheet Epoxy Floor Mica Sheet For Flooring Garage

color: multiple colour Package preview: Magnesium oxide content (%): Please contact us for more details shape: flakes application: epoxy paint, coating Al2O3 content (%): Please contact us for more details K2O content (%): Please contact us for more details Key words: Flash mica flakes Origin:...... -

Factory direct sales composite rock slab epoxy floor raw material artificial mica paint with composite mica can be customized size

port: Qingdao/Tianjin/Shanghai Magnesium oxide content (%): 0.5-0.8% brand: Shun Shun Oil absorption: 40-65% model: 6-60 mesh product name: Mica Al2O3 content (%): 28-33% size: 6-60 mesh payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram application: Plastic Cosmetics Pearlescent Pigments.....