Color high-quality spray or hand lay-up gel coat, suitable for ship model bathtub top glass fiberglass

- $3.39 / >=20 kilograms

- 20 kilograms

- Guangdong Good Resin Co., Ltd.

- Guangdong, China

- Mr

Product Detail

| Certificate: | Material Safety Data Sheet | property: | Pre-promotion and thixotropy |

| brand: | good resin | Gel time: | 8-18 minutes |

| payment terms: | L/C, Western Union, T/T, Western Union Alibaba Trade Assurance Paypal | Supply capacity: | 8000 kg gel coat per month |

| IF: | CH2-CHCl-]n | Packaging Details: | Material: Metal Drum Net Weight: 20kg/drum |

| Other names: | Iso-NPG gel coat | type: | Spray or hand lay-up, synthetic resin and plastic |

| Origin: | Guangdong, China | Package: | 20kg/barrel or 220kg/barrel |

| application: | Ship model bathtub countertops and other GRP | port: | Guangzhou/Shenzhen |

| CAS number: | 25608-12-2 | Shelf life: | 6 months |

| model: | GD-72# | color: | all colors are acceptable |

| product name: | Neopentyl Glycol Isophthalate Gel Coat | EINECS number: | 208-750-2 |

| Package preview: | purity: | 100% | |

| Health status: | 100% tested and working |

Ship Model Bathtub Table FRP High Quality Spray Type Gel Coat

Gel coat is made of unsaturated polyester (UP) adding pigments and thixotropic agents to disperse fiberglass reinforced plastics (FRP) and countertop paints to develop colored thixotropic products.

instruct:

1. Select the appropriate type of gel coat before use.

2. Thoroughly prepare the mold, the surface of the mold determines the surface of the product.

3. Stir the gel coat well before use, but the speed should be slow to avoid bubbles from stirring.

4. Before starting work, keep the gel coat and mold temperature at 16°C-30°C, and the ideal mold temperature should be 2°C-3°C higher than the gel coat temperature. This results in a smoother gel coat surface after curing.

5. The relative humidity in the workshop should be less than 80%, and the humidity will lead to the required curing temperature. In addition, it is necessary to prevent water accumulation on the surface of the mold.

6. The surface of the mold should be filled with wax, do not use release wax containing silicon. Water-soluble mold release wax must wait for its water to evaporate before applying gel coat.

7. Do not dilute with solvents, such as acetone. Small amounts of styrene (<2%) can be added if lower viscosities are required.

8. The amount of curing agent (MEKP) is generally 1-2%. If the amount of curing agent is too high or too low, the water resistance and weather resistance of the product will be reduced.

9. Wait for the color paste to ensure uniform and stable color. Accurately weigh the recommended amount and mix using low shear equipment. You can also use colored gel coats.

Click here to send us a quote for more details about Gel Coat

Related Products

-

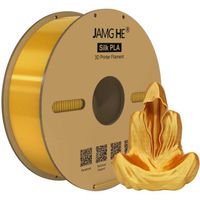

JAMGHE filament pla 175mm 1kg suitable for 3d printer filament pla filament 3d printer multi-color 3d pla filament

Product Description Product packaging Recommended products Why choose us Shenzhen Yongchanghe Technology Co., Ltd.It is a subsidiary of Meilianxing Technology Co., Ltd., a professional UV curing company with decades of R&D and manufacturing experience. One of our shareholders, Professor Li, has...... -

Jamghe Crown and Bridge Resin ColorA1 A2 A3 dental resin pmma white

model: DB-06, GTX-10 Sales Unit: Single item type: Composite resin and plastic, 3d crown resin purity: 100% Other Names: Photopolymer resin Product Name: Crown and bridge resin color: A1 A2 A3 White 3D Printer: LCD resin printer 2k 4k Origin: Guangdong, China Gross weight per piece: 1.500 kg Single.... -

High-speed resin Rapid Resin is suitable for fast resin 3D printer Saturn 3 ultra M5

application: Cartoon characters and models Package preview: type: Synthetic resins and plastics, photosensitive resins product name: High speed standard resin Place of origin: Guangdong, China model: 12k resin Supply capacity: 10,000 kg per week port: Shenzhen printing speed: Fast printing printer:.... -

High quality free sample glue yellow rosin glue for rosin/rosin

type: Synthetic resins and plastics grade: Industrial grade Place of origin: Shandong Province, China appearance: hard color: light yellow application: industry Other names: rosin purity: 100% model: ZH port: Tianjin Qingdao Name: yellow rosin gym EINECS number: 232-475-7 brand: Zhonghao Supply...... -

3D Printer Casting Resin Jewelry Liquid Casting/Wax Resin For LCD/DLP/SLA 3D Printer 1000ml Casting Resin China Factory

Supply capacity: 1000 kg per month weight: 1 kg per bottle model: BS9626 brand: Yi Zhi type: LCD DLP printer port: Shenzhen CAS number: 71281-65-7 color: yellow or green or red or customized payment terms: L/C, Western Union, T/T, MoneyGram Whatsapp or WeChat: 8615813803737 purity: 100% type:...... -

Ion exchange resin for water softener, RO system mixed bed resin post-treatment water softener, deionizer

type: ion exchange resin appearance: spherical beads Packaging Details: Coal-based activated carbon deodorant ctc80 granule price per ton 25kg PE/woven bag; 1000kg super sack; Certificate: NSF, SGS, TUV, REACH&RoHs EINECS number: ion exchange resin Supply capacity: 100 tons per month purity: 99%...... -

Solid water-soluble acrylic resin for water-based ink coating

model: other type: Synthetic fibers, synthetic resins and plastics, synthetic rubber IF: other CAS number: other Origin: Shandong Province, China Supply capacity: 1000 kg per day port: Shanghai Other names: Waterborne solid acrylic resin payment terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram...... -

High Wax 60% Jewelry Resin Pouring Casting No Cracking LCD DLP 3D Printer Resin Anycubic DWS nova 3d Printer Jewelry

usage: 3D printing feature: high precision product name: jewelry high wax resin model: HM-6020 application: jewelry casting Material: photopolymer Package preview: purity: 100% Origin: Guangdong, China sample: 1 sample Packaging Details: 500g/bottle 10 bottles/box Box size: 380*300*300mm Weight:...... -

Casting Solid Surface Materials Liquid Raw Polyester Resin for Countertops Tub Bath Bathroom Fittings

payment terms: L/C, T/T, Western Union port: Guangzhou usage: Bathroom Fittings and Solid Surface Materials purity: 76% brand: OK Other names: Unsaturated polyester resin Supply capacity: 800 tons of polyester resin per month Health status: 100% tested and working Accelerator mixing ratio:...... -

Mixing polyols with isocyanates for the production of high-density rigid foams

Other names: Polyurethane system model: MDI series Selected service: Free design, provide samples, foam training application: Soft foam, rigid foam, semi-rigid foam Packaging Details: Packed in sealed iron drum Material: Polyurethane system Supply capacity: 100,000 tons per month feature: Good......