Spray two-component polyurethane foam closed-cell raw material

- $1.50 / >=500 kilograms

- 500 kilograms

- Shandong Mingko Machinery Co., Ltd.

- Shandong, China

- Mr Jimmy Gao

Product Detail

| brand: | Brother Ming | application: | spray polyurethane foam |

| Storage stability: | 6 months | Dynamic viscosity (25°C): | 100-200mpa.s |

| usage: | construction, fibers and clothing, footwear and leather, packaging, transport, carpentry | Hydroxyl value: | 200-300mgKOH/g |

| IF: | -NHCOO- | Package preview: | |

| EINECS number: | 210-898-8 | Specific gravity (20°C): | 1.12-1.20 g/ml |

| place of origin; place of origin: | Shandong China | CAS number: | 9009-54-5 |

| model: | DQT-501C | Storage temperature: | 10-25℃ |

| DJD-105 mixed polyol: | 100 | Isocyanate: | 100-105 |

| Supply capacity: | 1000 tons per month | payment terms: | L/C, Western Union, T/T |

| Cream time/second: | 3-5 | Packaging Details: | Drums in wooden pallets open cell water based flexible flexible PU polyurethane spray foam for construction raw material polyurethane polyether polyol + isocyanate for rigid PU foam |

| Other names: | insulating polyurethane foam | Types of: | liquid glue |

| port: | Qingdao/Tianjin/Shanghai/Ningbo/Shenzhen | density: | 35-50 kg/m3 |

| Classification: | two-component adhesive | main ingreadient: | Polyurethane |

Spray Two-Component Polyurethane Foam Insulation PU Foam Introduction

Water-based polyurethane flexible foam is an environmentally friendly foam with water as the blowing agent, which has excellent properties such as low density (8~10kg/m 3 ), open cells, and flame retardant (B3 grade).

During the on-site spraying process, the small openings for breathing are filled with air, and will not produce toxic gases that destroy the ozone layer (traditional foaming agents: F-11, HCFC-141B), and are environmentally friendly and low-carbon new building materials.

This spray PU foam has properties such as heat insulation, gas barrier, moisture-proof heat insulation, waterproof, sound absorption, etc., and can give us a quieter, healthier, and more energy-efficient building.

It is suitable for various thermal insulation projects using spraying technology such as cold storage, tanks, large pipelines, and building walls.

Parameters of open-cell water-based flexible PU polyurethane spray foam for construction

physical properties

|

appearance Hydroxyl value mgKOH/g Dynamic viscosity (25℃) mpa.s Specific gravity (20℃) g/ml Storage temperature ℃ storage stability months |

Pale yellow to brown viscous liquid 200-300 100-200 1.12-1.20 10-25 6 |

Recommended ratio

|

|

body mass index |

|

DJD-105 blend polyol Isocyanate |

100 100-105 |

Response characteristics

(The system temperature is 20°C, the specific value varies with the process conditions)

|

cream time gel time |

3-5 6-10 |

bubble show

|

project |

testing method |

index |

|

spray density Closure rate Initial thermal conductivity (15°C) Compressive strength Adhesive strength elongation at break Dimensional stability 24h -20℃ 24h 70℃ water absorption Oxygen Index |

GB 6343 GB 10799 GB 3399 National standard/T8813 GB/T16777 GB/T9641 National standard/T8811

GB 8810 National standard 8624 |

>40kg/square meter3 ≥90% ≤24mW/(mK) ≥150kPa ≥120kPa ≥10% ≤1% ≤1.5% ≤3% ≥26 |

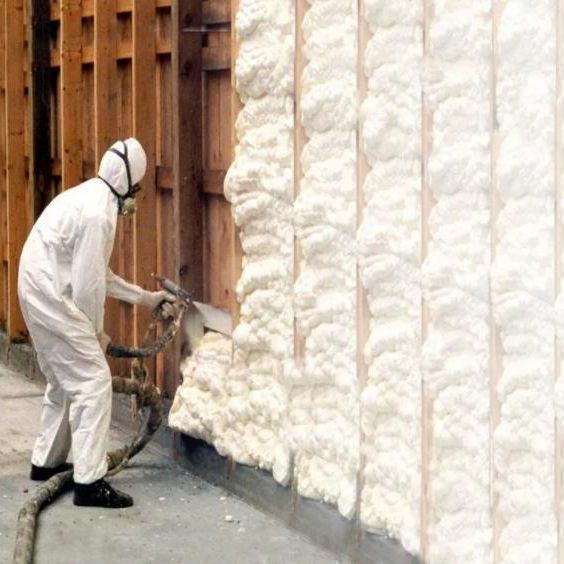

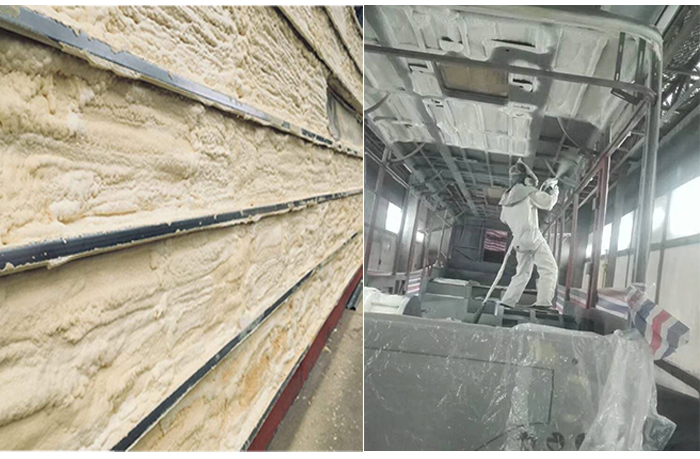

Picture of two-component polyurethane foam material

Related Products

-

Liquid Epoxy Resin Raw Material Price Industrial Resin Epoxy Resin Curing Agent Chemicals

Viscosity: Resin 1600cps Curing agent 100cps IF: C15H16O2C2H7ONC3H5OCl Package preview: Origin: Guangdong, China EINECS number: 230-391-5 Classification: Two-component adhesive Minimum order quantity: 20kg color: transparent model: YD-128 Chemical Abstracts Service number: 7085-85-0 usage:...... -

High Penetration Clear Epoxy Resin for Outdoor Gravel Driveway Epoxy Aggregate Paving Stone Floor Coating Resin 20kg Kit

Shelf life: 6 months Classification: Two-component adhesive Original Equipment Manufacturers: Provide OEM/ODM/label customization services Packaging Details: 15KG/3 gallon kit; 1.5 gallon; 5kg, 20kg kit; 25kg; 15 gallon; 200kg. Support OEM/ODM customization. Origin: Guangdong, China usage: Suitable.... -

Recina Epoxica Para Pisos Epoxy AB Glue Self-Leveling Floor Kit for Concrete and Cement Floor Coating

Product Category: 2 parts Chemical Abstracts Service number: 38891-59-7 Place of origin: Guangdong, China port: Shenzhen feature: Good fluidity, low viscosity, bright surface Performance: No yellowing Supply capacity: 1000 tons per month color: transparent Classification: Two-component adhesive...... -

Crystal AB glue epoxy resin/transparent liquid epoxy resin

The mixing ratio: A:B=3:1 model: 318AB-9 Feature 1: Automatic defoaming Origin: Guangdong, China type: epoxy resin Packaging Details: 5kg per bottle; 20kg/carton 20kg/barrel 200kg/barrel Delivery time: 3 days color: to clear usage: Construction, Fibers and Clothing, Footwear and Leather, Packaging,.... -

Crystal Clear/Epoxy-Resin-Table-Top Deep Casting Epoxy Resin Suppliers

payment terms: L/C, Western Union, D/P, T/T, Paypal The mixing ratio: A:B=3:1 EINECS number: 231-072-3 Other names: epoxy resin CAS number: 38891-59-7 Material: epoxy resin Package preview: IF: C15H16O2C2H7ONC3H5OCl Classification: two-component adhesive type: two components model: 312AB-6-N usage:.... -

Transparent 3d epoxy floor paint transparent epoxy resin liquid resin

The mixing ratio: A:B=3:1 payment terms: Western Union, T/T, MoneyGram main ingreadient: epoxy resin usage: Construction, Fibers and Clothing, Woodworking brand: De Jianbang Supply capacity: 100,000 kg per month IF: mixture color: Transparent liquid port: Qingdao/Shanghai/Yiwu/Shenzhen CAS number:..... -

Holographic Glitter Floor Coating Epoxy Glitter Floor

EINECS number: other Classification: two-component adhesive brand: Mountain bike JZJ product name: Holographic Glitter Floor Coating Epoxy Glitter Floor CAS number: 61788-97-4 payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram color: to clear usage: Construction, transportation, floor...... -

Rhinestone crafts multi-purpose strong glue cloth metal stone manicure wood glass B7000 jewelry bead glue

Package preview: MOQ: 3 payment terms: Western Union, T/T Origin: China sample: available delivery time: within 5 working days OEM/Design Manufacturer: OEM ODM private label model: M42 main ingreadient: acrylic fiber product name: B7000 glue Pay: Trade Assurance. Western Union. TT Packaging...... -

Strong glue ab glue transparent liquid crystal epoxy resin good quality and good price

port: Hong Kong port usage: put up color: Colorless translucent/colorless transparent Density (g/m3): 1.07+0.05/0.95+0.03 type: Resin 312A-H3/curing agent 312B-H3, AB glue Other names: Adhesive IF: [CH(CH2Cl)CH2O]n Classification: other adhesives model: 312AB-H3 brand: benu Mixing ratio (weight...... -

Spray Foam Insulation Polyurethane Foam Kit (650-215 Board Feet) Izotup 200 Quick Rise (QR) with Mask Cylindrical Tube Material

payment terms: wire transfer usage: Construction, Fibers and Clothing, Footwear and Leather, Packaging, Transport, Carpentry Name: Spray Polyurethane Foam Kit Foam Type: Obturator type: closed cell foam size: 41 lbs / 16" x 16" x 9" / 215 BdFt Classification: two-component adhesive EINECS number:......