High-density polyurethane raw material culture stone two-component polyether polyol PU foam joint insulation

-

$5.40 / 1 - 199 kilograms

$2.80 / 200 - 17599 kilograms

$2.10 / 17600 - 39999 kilograms

$1.81 / >=40000 kilograms - 1 kilogram

- Guangdong Henggeli Technology Co., Ltd.

- Guangdong, China

- Ms jinpei cen

Product Detail

| CAS number: | 9006-11-3 | grade: | Second |

| product name: | PU asbestos | IF: | C18H22O2 |

| Supply capacity: | 10000 kg per day | The mixing ratio: | 1:01 |

| Package: | 200L/barrel | port: | Guangzhou |

| Isocyanate: | 100-105 | Package preview: | |

| brand: | Changwei | Origin: | Guangdong, China |

| Other names: | mixed polyol | type: | Synthetic fibers, synthetic resins and plastics, synthetic rubber, polyurethane |

| model: | HGL-131 | Shelf life: | 12 months |

| use: | Filling, thermal insulation, waterproof, fireproof | purity: | 99.99% |

| EINECS number: | 3907299090 | payment terms: | L/C, Western Union, T/T |

| color: | light yellow |

Product Description

Other names: | Rigid polyurethane blend polyols for imitation wood or polyurethane stone |

IF: | polyurethane foam |

EINECS number: | Polyurethane insulation sponge |

Origin: | Guangdong, China |

Classification: | two-component adhesive |

main ingreadient: | Polyurethane |

usage: | Imitation wood or PU stone |

brand: | Changwei |

model: | HGL-101 |

type: | liquid glue |

product name: | rigid PU stone foam |

Shelf life: | 12 months |

Package: | 220L/barrel |

grade: | Second |

color: | light yellow |

The mixing ratio: | 1:1 |

Isocyanate: | 100-105 |

Installation Notes

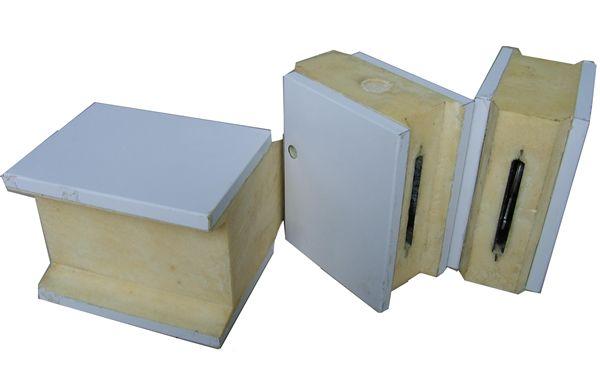

Imitation wood or PU stone foam

Rigid polyurethane hybrid polyol for wood filling, is a two-component closed-cell polyurethane foam system. This product is a water-based system, which is pre-mixed with polyether polyol, silicone surfactant, catalyst and water. It is suitable for imitation wood, furniture filling, handicraft filling and artificial cultural stone production. Its advantages are: high density, high square number, no shrinkage of the produced products, good dimensional stability, long service life, custom fireproof cultural stones, and very high practicability.

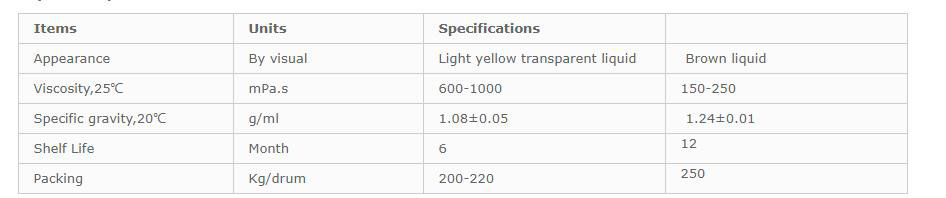

physical properties

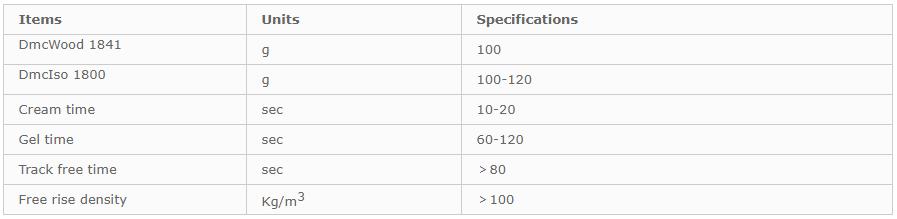

React Performance (Manual)

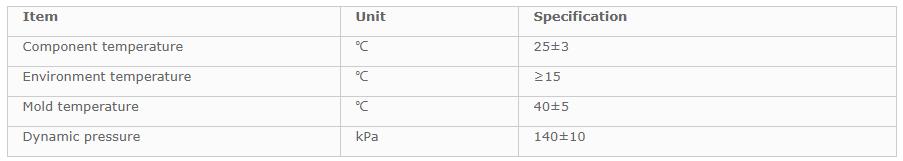

processing information

It is recommended to use a high pressure foaming machine. Chemicals should be adjusted to correct temperature

22-27°C to ensure reactivity and viscosity suitable for processing.

The mixing pressure of the two components must be set at 130-150 bar.

The recommended mold temperature is 35-45°C to ensure good foaming properties.

22-27°C to ensure reactivity and viscosity suitable for processing.

The mixing pressure of the two components must be set at 130-150 bar.

The recommended mold temperature is 35-45°C to ensure good foaming properties.

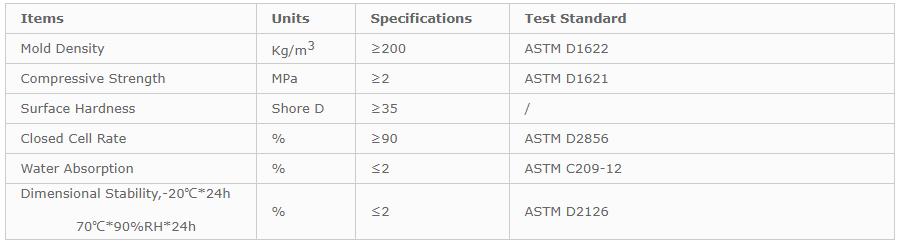

foam properties

The above test data was generated under typical laboratory or field conditions for this application. They are believed to be correct, but variations in data due to processing or changes in environmental conditions cannot be excluded. Customers remain responsible for their own interpretation of the data and the suitability of chemicals for their particular operations. Handling and Storage Mixed polyols should be kept tightly closed when not in use to protect from moisture. Drums must be stored indoors to protect the material from water ingress, frost and direct sunlight. Polyol has a shelf life of 6 months under temperature conditions and in properly sealed containers. The best storage temperature is 10-30°C.

application

Insulation Pipe

incubator

wine cabinet

library committee

Sealants

soft foam

VIEW MORE

Related Products

-

High-speed resin Rapid Resin is suitable for fast resin 3D printer Saturn 3 ultra M5

application: Cartoon characters and models Package preview: type: Synthetic resins and plastics, photosensitive resins product name: High speed standard resin Place of origin: Guangdong, China model: 12k resin Supply capacity: 10,000 kg per week port: Shenzhen printing speed: Fast printing printer:.... -

High quality free sample glue yellow rosin glue for rosin/rosin

type: Synthetic resins and plastics grade: Industrial grade Place of origin: Shandong Province, China appearance: hard color: light yellow application: industry Other names: rosin purity: 100% model: ZH port: Tianjin Qingdao Name: yellow rosin gym EINECS number: 232-475-7 brand: Zhonghao Supply...... -

3D Printer Casting Resin Jewelry Liquid Casting/Wax Resin For LCD/DLP/SLA 3D Printer 1000ml Casting Resin China Factory

Supply capacity: 1000 kg per month weight: 1 kg per bottle model: BS9626 brand: Yi Zhi type: LCD DLP printer port: Shenzhen CAS number: 71281-65-7 color: yellow or green or red or customized payment terms: L/C, Western Union, T/T, MoneyGram Whatsapp or WeChat: 8615813803737 purity: 100% type:...... -

Ion exchange resin for water softener, RO system mixed bed resin post-treatment water softener, deionizer

type: ion exchange resin appearance: spherical beads Packaging Details: Coal-based activated carbon deodorant ctc80 granule price per ton 25kg PE/woven bag; 1000kg super sack; Certificate: NSF, SGS, TUV, REACH&RoHs EINECS number: ion exchange resin Supply capacity: 100 tons per month purity: 99%...... -

Solid water-soluble acrylic resin for water-based ink coating

model: other type: Synthetic fibers, synthetic resins and plastics, synthetic rubber IF: other CAS number: other Origin: Shandong Province, China Supply capacity: 1000 kg per day port: Shanghai Other names: Waterborne solid acrylic resin payment terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram...... -

High Wax 60% Jewelry Resin Pouring Casting No Cracking LCD DLP 3D Printer Resin Anycubic DWS nova 3d Printer Jewelry

usage: 3D printing feature: high precision product name: jewelry high wax resin model: HM-6020 application: jewelry casting Material: photopolymer Package preview: purity: 100% Origin: Guangdong, China sample: 1 sample Packaging Details: 500g/bottle 10 bottles/box Box size: 380*300*300mm Weight:...... -

Casting Solid Surface Materials Liquid Raw Polyester Resin for Countertops Tub Bath Bathroom Fittings

payment terms: L/C, T/T, Western Union port: Guangzhou usage: Bathroom Fittings and Solid Surface Materials purity: 76% brand: OK Other names: Unsaturated polyester resin Supply capacity: 800 tons of polyester resin per month Health status: 100% tested and working Accelerator mixing ratio:...... -

Mixing polyols with isocyanates for the production of high-density rigid foams

Other names: Polyurethane system model: MDI series Selected service: Free design, provide samples, foam training application: Soft foam, rigid foam, semi-rigid foam Packaging Details: Packed in sealed iron drum Material: Polyurethane system Supply capacity: 100,000 tons per month feature: Good...... -

IFUN Dark Green 100% Burn Out Jewelry Casting Resin Using 405nm DLP 3D Resin Printer for Sterling Silver and Gold Bracelets

application: DLP 3D printer delivery time: 5-7 days use: Sterling Silver and Gold Casting Origin: China model: iF3170 color: dark green Origin: China payment terms: wire transfer Package preview: product name: jewelry casting resin feature: 100% easy to burn out type: Synthetic resins and plastics..... -

Jewelry High Wax Casting Resin High Precision UV 405nm 3D Printer Resin Easy Casting DLP LCD High Wax Resin

payment terms: Western Union, T/T usage: 3D printing CAS number: 61788-97-4 application: jewelry casting weight: 1000 grams product name: Jewelry High Wax Casting Resin color: green feature: high precision Packaging Details: 1 kg/bottle 10 bottles/box Box size: 380*300*300 mm Weight: 12 kg Package.....